What materials are commonly used in rapid molding processes?

What Materials Are Commonly Used in Rapid Molding Processes?

Material Selection in Rapid Molding: Speed Meets Functionality

Rapid molding—encompassing techniques like rapid injection molding and soft tooling—is designed for producing functional prototypes or low-to-mid volume parts within days. Material choice is critical in balancing speed, cost, mechanical performance, and end-use requirements. Neway’s rapid molding services support a wide spectrum of thermoplastics and elastomers suitable for real-world testing and small-batch production.

Common Thermoplastics Used in Rapid Molding

ABS (Acrylonitrile Butadiene Styrene)

General-purpose thermoplastic with good impact resistance and machinability

Applications: Consumer electronics housings, automotive trim

PC (Polycarbonate)

High-impact strength and optical clarity; heat resistant up to 135°C

Applications: Lighting covers, lenses, impact-resistant enclosures

PA (Nylon 6, Nylon 66)

High tensile strength, excellent wear resistance, and chemical stability

Applications: Gears, bushings, structural mechanical parts

POM (Acetal/Delrin)

Low friction, excellent dimensional stability, and rigidity

Applications: Bearings, automotive fuel systems, fasteners

PEEK (Polyether Ether Ketone)

High-performance polymer with thermal resistance up to 250°C and strong mechanical properties

Applications: Medical devices, aerospace parts, electrical insulators

PP (Polypropylene)

Lightweight, chemical-resistant, and flexible

Applications: Living hinges, fluid containers, medical packaging

TPE/TPU (Thermoplastic Elastomers)

Rubber-like flexibility, abrasion resistance, and excellent rebound

Applications: Seals, gaskets, wearable device components

PBT (Polybutylene Terephthalate)

Excellent electrical properties and dimensional stability

Applications: Connectors, automotive sensors, appliance parts

Specialty and Engineering Plastics

Ultem (PEI): Flame-retardant and high heat resistance for aerospace and medical

LCP (Liquid Crystal Polymer): Ideal for microelectronic and ultra-thin molded parts

PSU, PPSU: Used where high steam resistance or sterilization cycles are needed

Factors Influencing Material Selection

Tooling Temperature Soft tooling (e.g., aluminum molds) limits the use of very high-temperature plastics like PEEK unless specially engineered.

Part Complexity Flexible materials like TPU are chosen for complex geometries and undercuts.

End-Use Requirements Materials must match thermal, mechanical, or regulatory standards based on application.

Integrated Services for Material Optimization

Neway enhances rapid molding outcomes through:

Material Selection Consulting for balancing speed, cost, and performance

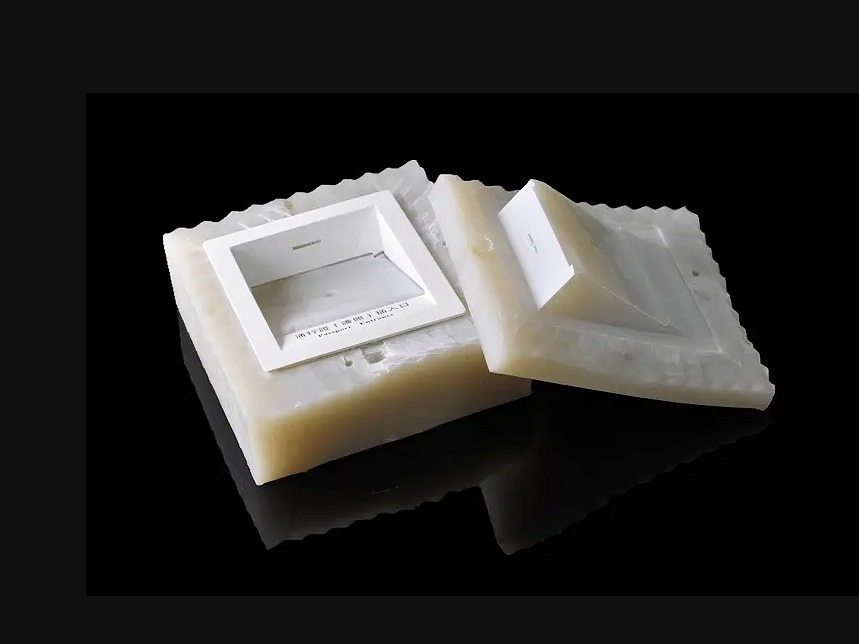

Rapid Tooling with aluminum or hybrid steel molds

Post-Molding Services like inspection, machining, and coating

With delivery in as fast as 7 days and ±0.05 mm accuracy, Neway’s rapid molding solutions support both prototype testing and functional end-use part production.