Is rapid molding suitable for high-volume production?

Is Rapid Molding Suitable for High-Volume Production?

Understanding the Role of Rapid Molding in Production Scaling

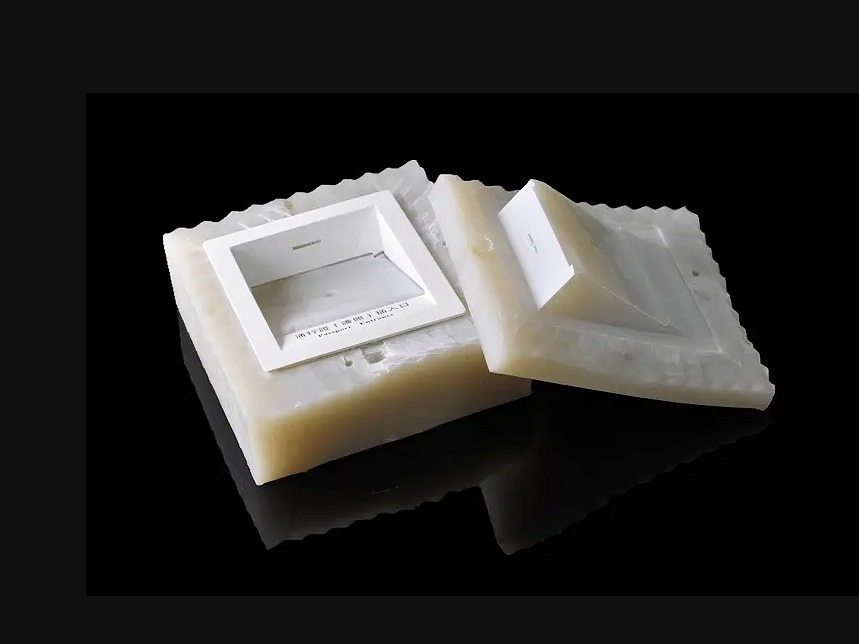

Rapid molding is primarily engineered for low- to mid-volume production, typically ranging from 50 to 10,000 parts. It uses soft tooling—often aluminum or hybrid steel inserts—to accelerate mold fabrication and reduce costs. While this approach is ideal for fast iteration, bridge production, and product validation, it does have limitations when applied to high-volume manufacturing.

Key Factors Limiting High-Volume Suitability

Tooling Durability Aluminum molds used in rapid molding are cost-efficient but wear out faster than hardened steel.

Typical mold life: 5,000–20,000 cycles depending on material and part complexity

In contrast, steel tooling for traditional injection molding can last 500,000+ cycles

Cycle Time Optimization Rapid molds are not optimized for aggressive cooling systems or high-speed automation.

Result: Longer cycle times per shot in comparison to hardened steel molds

Material Compatibility Some engineering-grade polymers like PEEK or Ultem require elevated mold temperatures, which may stress aluminum tools and reduce tool life in high-volume runs.

Maintenance Frequency Softer molds require more frequent maintenance and inspections in long-term use, adding labor and downtime.

Ideal Use Cases for Rapid Molding

Bridge Production: Temporary solution while mass production tooling is in development

Design Iteration: Fast response to engineering changes without re-machining hard steel molds

Market Testing: Low-risk production of initial batches for feedback or pilot launches

Customization: Short runs of variants without high tooling investment

When to Transition to Traditional Molding

If your production exceeds 50,000 units annually, consider transitioning to steel tooling to achieve:

Lower cost per part over long runs

Reduced cycle time through advanced cooling systems

Extended mold life with fewer repairs

Neway’s Scalable Molding Support

Neway provides end-to-end solutions from rapid prototyping to full-scale production:

Rapid Molding Services for bridge production

Injection Molding for high-volume scalability

Material Consultation to ensure long-term tool and part performance

With ±0.05 mm precision, tool life prediction, and flexible production plans, Neway helps manufacturers seamlessly scale from prototypes to mass production.