How does overmolding differ from traditional injection molding?

How Does Overmolding Differ from Traditional Injection Molding?

While both overmolding and traditional injection molding use similar equipment and principles, they serve different design and performance needs. Overmolding is a multi-material molding technique that enhances functionality, comfort, and durability, going beyond the single-material scope of conventional injection molding.

Here’s a detailed comparison of the two:

1. Material Complexity

Traditional Injection Molding: Uses a single type of plastic (e.g., ABS, PC, Nylon) to form the entire part.

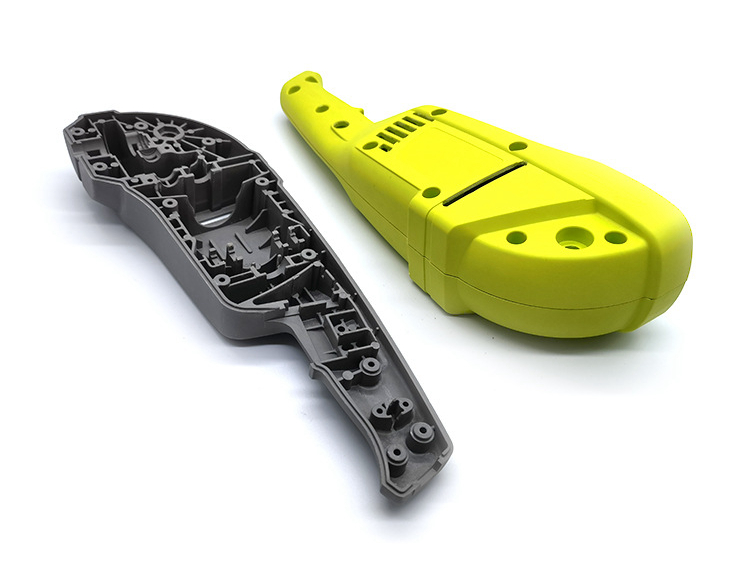

Overmolding: Involves at least two materials: a rigid substrate (first shot) and a soft or functional overmold (second shot), such as TPE, TPU, or silicone rubber.

2. Process Sequence

Traditional Injection Molding: The mold is filled once with molten plastic, which cools and solidifies into the final part.

Overmolding: The process is two-stage:

Mold the rigid substrate

Load it into a second mold (or second cavity in a multi-shot mold) for overmolding a second material onto or around the first part

3. Functionality and Design Outcome

Traditional Injection Molding: Provides structural and cosmetic parts made from one plastic. It’s ideal for enclosures, housings, brackets, and general industrial components.

Overmolding: Adds ergonomic grip, shock absorption, sealing, and aesthetic contrast. It eliminates the need for fasteners, adhesives, or secondary operations.

4. Applications

Traditional Injection Molding:

Appliance housings

Electronic casings

Mechanical components

Overmolding:

Medical device grips

Automotive knobs with soft-touch overlays

Waterproof connectors

Industrial tool handles

5. Tooling and Cost Considerations

Traditional Injection Molding: Single-material molds are simpler and less expensive to build and maintain.

Overmolding: Requires dual-cavity or multi-shot molds, increasing initial tooling investment—but it reduces assembly time and improves part integration.

Why It Matters

Companies like Neway Precision offer both techniques depending on your part’s functional and aesthetic requirements. Our consultative engineering support helps you determine whether traditional molding or overmolding is better suited for your application, based on factors like cycle time, part complexity, material bonding, and lifecycle cost.