Which materials are best suited for CNC machining in critical applications?

Which Materials Are Best Suited for CNC Machining in Critical Applications?

Overview of Material Requirements for Precision CNC Machining

Critical applications—such as aerospace, medical, defense, and energy—demand materials that offer a balance of mechanical strength, dimensional stability, corrosion resistance, and machinability. The CNC machining process must deliver tight tolerances (±0.01 mm or better) while preserving surface integrity and material performance under operational stresses.

Top CNC Machining Materials for High-Performance Applications

Material | Key Properties | Suitable Applications |

|---|---|---|

Stainless Steel (316L, 17-4 PH) | Corrosion-resistant, high strength, bio-compatible | Medical implants, food-grade components, aerospace |

Titanium (Grade 5 / Ti-6Al-4V) | High strength-to-weight, corrosion resistance, bio-compatibility | Aircraft parts, orthopedic screws, turbine blades |

Inconel (625, 718) | Heat resistance >980°C, creep resistance, oxidation stability | Jet engine parts, pressure vessels, nuclear components |

Aluminum Alloys (6061, 7075) | Lightweight, high machinability, corrosion resistance | Avionics, automotive parts, robotics housings |

Tool Steels (H13, D2) | High hardness, wear resistance, dimensional stability | Injection molds, cutting tools, dies |

Copper Alloys (C110, C145) | Excellent conductivity, moderate strength, corrosion resistance | RF components, electrical contacts, heat exchangers |

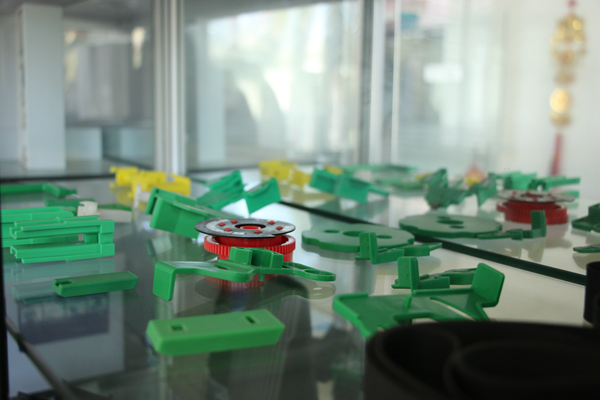

Engineering Plastics (PEEK, Ultem) | Lightweight, chemical and radiation resistance, insulative | Medical tools, semiconductor components, satellites |

Key Selection Criteria

Mechanical Performance High-stress parts need high yield strength and fatigue resistance. Titanium Grade 5 offers >895 MPa yield strength with excellent thermal stability.

Thermal Stability Inconel 718 and H13 maintain dimensional accuracy above 700°C, ideal for high-temperature environments.

Corrosion Resistance 316L stainless and PEEK withstand corrosive chemicals or marine environments without compromising part longevity.

Machinability While materials like Inconel and Titanium are harder to machine, CNC setups with optimized speeds and coated tools (e.g., TiAlN-coated end mills) enable precision without excessive tool wear.

Certifications & Traceability For industries like aerospace or medical, materials must meet standards like ASTM F136 (for Ti-6Al-4V) or AMS 5643 (for 17-4 PH stainless).

CNC Support for Critical Applications

Neway provides precision machining with material expertise, including:

Stainless Steel CNC Machining with ISO 2768 tolerances

Titanium CNC Machining for aerospace and medical-grade parts

Superalloy Machining for heat-resistant, high-load environments

With ±0.01mm accuracy, advanced quality control, and certified global material sourcing, Neway ensures your critical components meet the highest industry demands.