What industries benefit most from adopting 3D printing?

What Industries Benefit Most from Adopting 3D Printing?

Unlocking Competitive Advantages Through Additive Manufacturing

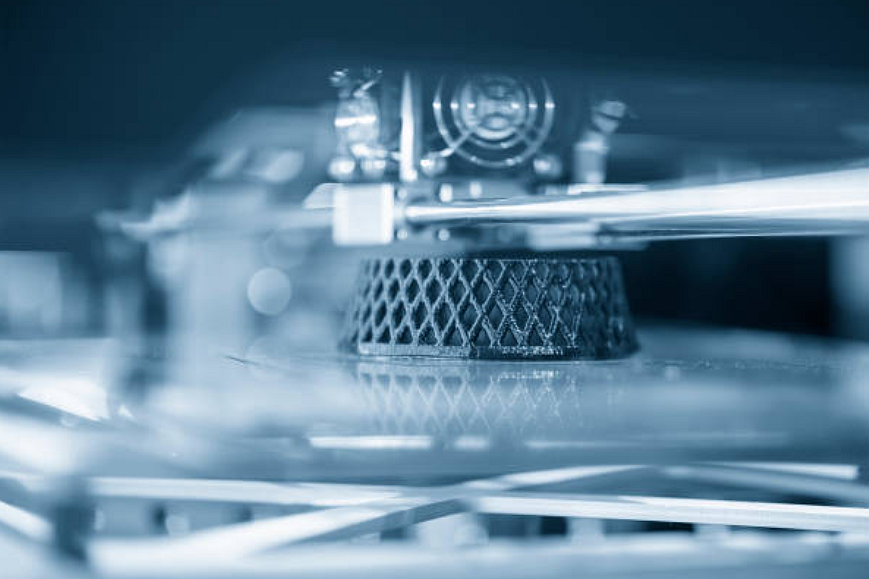

3D printing—also known as additive manufacturing—has rapidly evolved from a prototyping tool into a mainstream production method across multiple industries. By enabling design freedom, rapid iteration, and material efficiency, 3D printing services significantly reduce time-to-market and manufacturing costs for complex, custom, or low-volume parts.

Aerospace and Defense

Why it benefits: Lightweight structural optimization, part consolidation, and on-demand spares.

Typical applications: Fuel nozzles, brackets, ducting, turbine blades.

Aerospace OEMs report up to 60% weight reduction and 70% lead time cuts using metal 3D printing for low-run critical components.

Medical and Dental

Why it benefits: Customization, biocompatibility, and precision.

Typical applications: Orthopedic implants, surgical guides, dental crowns.

Materials used: PEEK, Titanium Grade 23, biocompatible resins.

3D printing enables patient-specific solutions, reducing surgical time and improving implant performance.

Automotive and Motorsports

Why it benefits: Lightweighting, tooling reduction, and rapid iteration.

Typical applications: Intake manifolds, jigs and fixtures, prototypes.

Materials used: Nylon PA12, Carbon-fiber reinforced filaments, Aluminum alloys.

OEMs leverage 3D printing to reduce prototyping cycles by 80% and bring EV models to market faster.

Consumer Electronics

Why it benefits: Miniaturization, custom casings, and fast design changes.

Typical applications: Enclosures, connectors, antenna structures.

3D printing enables flexible manufacturing in fast-paced tech markets with frequent model refreshes.

Industrial Equipment and Tooling

Why it benefits: Low-volume spares, mold inserts, and conformal cooling.

Typical applications: Custom jigs, MRO parts, tooling components.

Materials used: Tool steels, Ultem (PEI), Stainless steel

Facilities using 3D-printed tooling report over 50% faster cycle times and improved equipment uptime.

Supporting Services for Industry-Specific 3D Printing

Neway offers tailored additive manufacturing services for each sector:

Aerospace 3D Printing for certified superalloy parts

Medical-Grade CNC & 3D Printing for biocompatible components

Prototyping Services to accelerate design validation

Material Selection Guide to choose the right polymer, metal, or ceramic for your application

With global delivery, ISO-certified processes, and ±0.01 mm accuracy, Neway ensures consistent, industry-ready additive manufacturing.