What Are the Defects and Solutions of 3D Printing Services

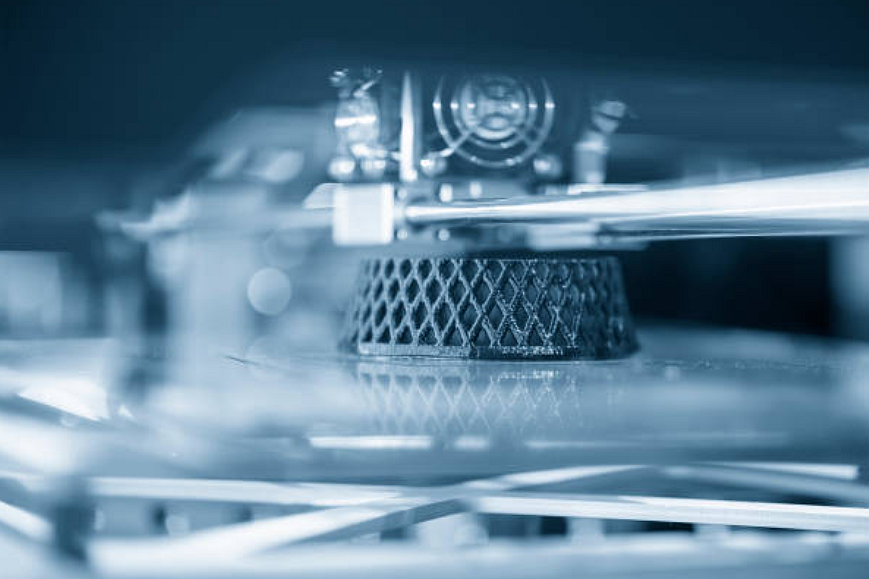

3D printing has revolutionized manufacturing and prototyping processes across various industries in recent years. Neway, a leading provider of diverse production services, offers 3D printing prototyping services as part of its rapid prototyping service. While 3D printing is a cutting-edge technology with numerous benefits, it's essential to acknowledge that, like any manufacturing process, it's with challenges. In this article, we will delve into the common defects in 3D printing and explore practical solutions to address these issues, all while keeping Neway's commitment to quality at the forefront.

Layer Adhesion Issues

One of the early challenges in 3D printing was inconsistent layer adhesion, resulting in weak final products. Factors such as improper temperature control, material composition, and printer calibration contribute to this issue.

Solution: Neway's experts meticulously calibrate printer settings, ensuring optimal temperature and material flow. Additionally, Neway guarantees strong layer adhesion for every print by selecting materials suited for specific applications.

Warping and Curling

Warping and curling occur due to differential cooling rates in larger objects or those with flat bases. It leads to distorted shapes and compromised dimensional accuracy.

Solution: Neway employs heated print beds to maintain uniform cooling, minimizing warping risks. Alongside this, careful pre-printing preparation, including adhesion aids and support structures, prevents deformation, producing flawless prints.

Inaccurate Dimensions

Precision is paramount in 3D printing, especially for functional parts. Inaccurate dimensions can result from mechanical printer play, material expansion, and scaling issues.

Solution: Neway's dedication to precision is evident in printer calibration that minimizes mechanical play and thermal expansion effects. Rigorous testing ensures that every printed object adheres to exact dimensions, setting industry benchmarks.

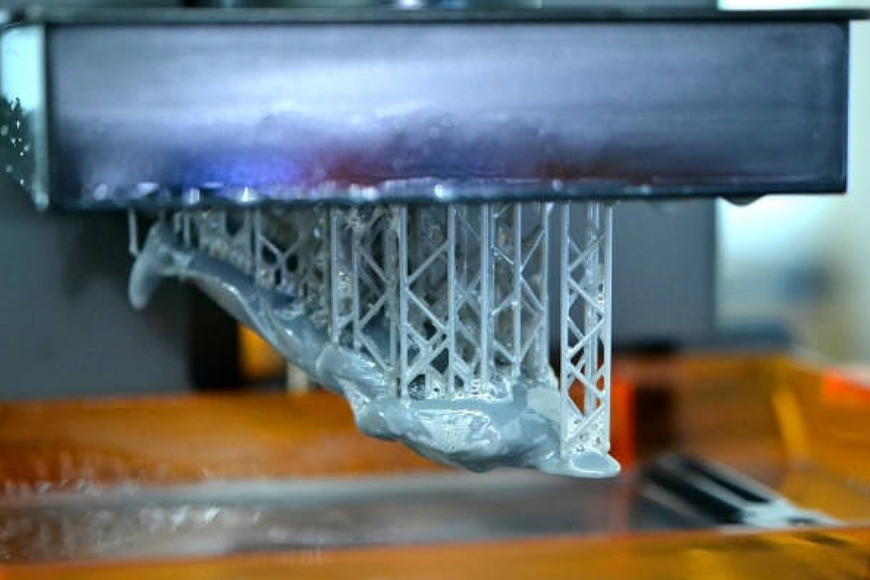

Stringing and Overhangs

Stringing, the formation of thin strands between separate parts, and overhangs, unsupported structures, compromise the visual appeal and functionality of prints.

Solution: Neway's engineers combat stringing with retraction settings, reducing filament oozing. Additionally, strategic design modifications and well-placed support structures ensure overhangs are adequately supported, yielding cleaner, more accurate prints.

Print Delamination

Print delamination, where layers separate, weakens the final product. Inadequate adhesion, cooling, or high printing speeds contribute to this issue.

Solution: Neway's profound understanding of materials and printing parameters prevents Delamination. Optimized cooling settings, layer bonding techniques, and meticulous process control create robust and durable prints.

Z-Wobble

Z-wobble manifests as uneven layers due to inconsistent movement of the print bed or extruder, resulting in a visibly layered finish.

Solution: Neway employs precision engineering to minimize Z-wobble, ensuring smooth and even layering. Rigorous maintenance of printer components guarantees consistent movement, yielding impeccable surface quality.

Nozzle Clogging

Nozzle clogging arises from filament debris, leading to inconsistent extrusion and incomplete prints.

Solution: Neway's regular maintenance practices prevent nozzle clogging. Filament quality control and proper ventilation systems make printing seamless, resulting in pristine prints.

Material Compatibility

Using incompatible materials can result in poor print quality, nozzle jams, and material wastage.

Solution: Neway's material expertise ensures the compatibility of materials with printers: detailed material selection and thorough testing guarantee high-quality prints, minimizing production waste.

Infill Density Variation

Inconsistent infill density affects the structural integrity of prints, impacting strength and weight distribution.

Solution: Neway employs meticulous infill settings and optimization techniques. It guarantees consistent density distribution, enhancing part strength and durability.

Printing Speed and Quality

Rapid printing can compromise surface quality and fine details, affecting the overall aesthetics of the print.

Solution: Neway balances printing speed and quality by optimizing slicing parameters. This results in visually appealing prints without compromising production efficiency.

Neway 3D Printing Prototyping Assurance

As the 3D printing industry continues to evolve, so do the challenges and solutions associated with this innovative technology. With its deep expertise in various production services, including 3D printing, Neway is committed to delivering exceptional results to its clients. By addressing common defects through careful calibration, material selection, and process optimization, Neway consistently provides high-quality 3D printed prototypes and parts that meet the demands of modern manufacturing. Through its dedication to innovation and excellence, Neway remains a stalwart partner in bringing creative ideas to life through the power of 3D printing.