Flawless Finishes: Ensuring Superior Surface Quality with Advanced Metal Bending

Introduction

In precision metal fabrication, achieving flawless surface finishes is crucial to a product's performance, aesthetics, and durability. Advanced metal-bending techniques greatly influence surface quality by minimizing defects and enhancing component value. Manufacturers across various sectors, including aerospace, automotive, medical, and consumer electronics, leverage these processes to deliver products with exceptional standards, often combined with specialized treatments such as anodizing.

The Role of Surface Quality in Metal Bending

Superior surface quality directly impacts the functionality, reliability, and marketability of metal products. Industries such as automotive and medical devices rely on smooth, defect-free surfaces to prevent corrosion, contamination, and premature wear, thereby extending component lifespan and enhancing overall performance. High-quality surface finishes, achieved through precision techniques such as CNC machining, significantly enhance consumer perception and product value.

Factors Affecting Surface Quality in Metal Bending

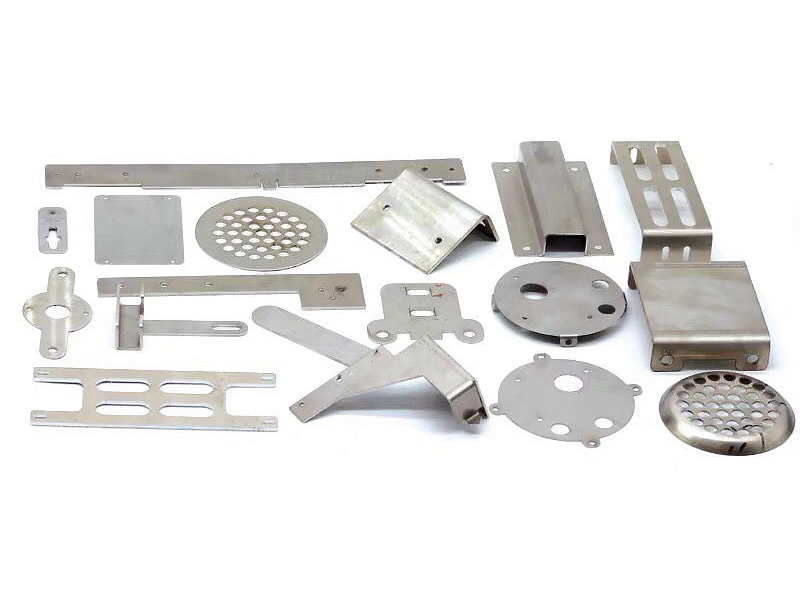

Material Selection

Selecting suitable materials is essential for obtaining superior surface finishes. Metals like aluminum, stainless steel, copper alloys, and specialty materials such as Inconel each possess distinct bending characteristics, which influence surface integrity. Choosing high-quality, consistent materials minimizes common surface defects such as cracking, discoloration, and scratches, ensuring optimal final results.

Tooling Precision and Condition

Surface quality is significantly impacted by tooling precision and maintenance. Worn or inadequately maintained tools often cause imperfections, such as marks or surface deformation. Regular tool inspections, sharpening, cleaning, and proper storage practices, possibly guided by mechanical design consultations, ensure consistently flawless finishes.

Machine Calibration and Maintenance

Accurate machine calibration controls bending parameters and ensures consistent surface finishes. Precise machine calibration prevents errors and maintains optimal bending parameters, preventing common defects such as surface irregularities or spring-back, which often occur in industries requiring stringent quality standards like medical devices manufacturing.

Technological Innovations Enhancing Efficiency

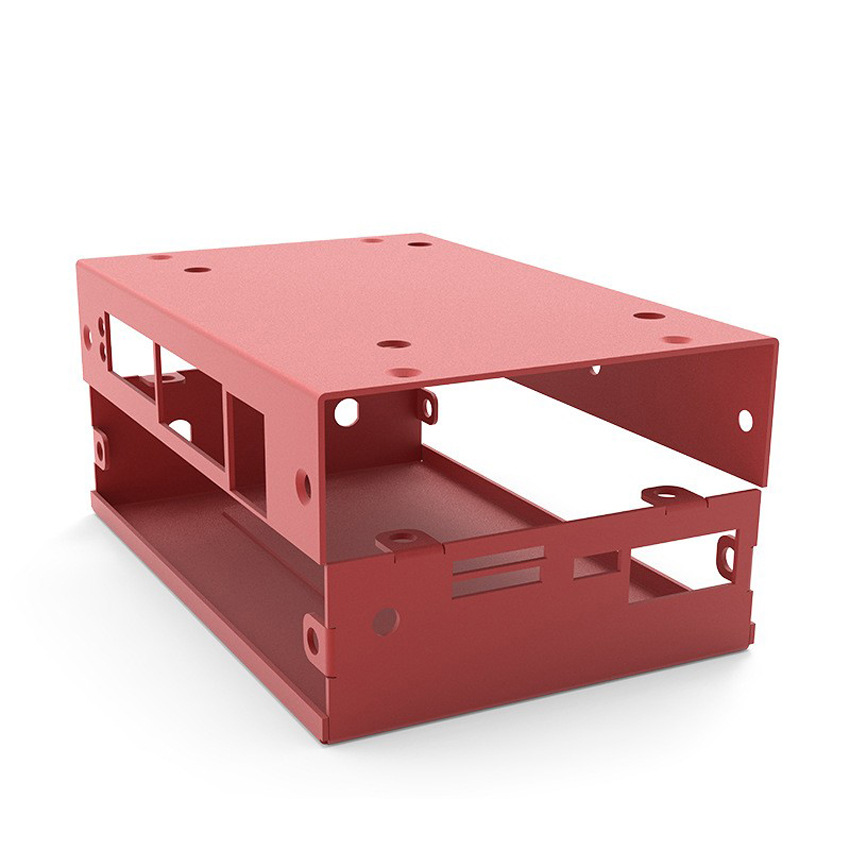

CNC Metal Bending Machinery

Computer Numerical Control (CNC) bending technology significantly improves surface finishes by offering precise control and repeatability. CNC machines eliminate manual errors by precisely managing bending angles and sequences, ensuring consistency across production runs. This technology is particularly advantageous in sectors that demand precision, such as aerospace manufacturing, by reducing surface defects and enhancing overall productivity.

Laser-assisted Bending Technology

Laser-assisted bending provides exceptional surface quality by precisely controlling heat application, minimizing material stress, and reducing defects. This advanced method is particularly beneficial for high-performance alloys, including nickel-based alloys, which are commonly used in aerospace and energy applications where maintaining structural integrity and surface smoothness is crucial.

Robotic Bending Solutions

Robotic systems enhance surface finishes through consistent precision and repeatability. Automation eliminates the variability inherent to manual processes, significantly reducing human-induced errors and ensuring consistent surface quality—crucial in high-volume production industries, such as automotive manufacturing.

Techniques to Optimize Surface Finishes

Optimized Material Handling

Proper handling techniques prevent surface damage before and during bending processes. Implementing careful material management and ensuring controlled transportation reduces scratches and contamination, thereby maintaining pristine surface conditions suitable for industries with strict hygiene requirements, such as the consumer electronics sector.

Appropriate Lubrication

Using appropriate lubricants minimizes friction between metal surfaces and tooling during bending, thereby significantly reducing the potential for surface imperfections. Lubricants selected according to material type and bending requirements enhance finish quality by preventing surface scratches, marks, and deformation.

Precise Control of Bending Speed and Force

Accurate control over bending speed and force settings ensures optimal surface conditions. Excessive force or incorrect speeds often result in visible defects such as cracking or wrinkling. Manufacturers can avoid these issues by carefully setting parameters guided by precise bending simulations often used in precision prototyping.

Inspection and Quality Assurance Techniques

Traditional Inspection Methods

Visual and tactile assessments are traditional yet essential methods for inspecting surface finishes, enabling the effective identification of visible defects, such as scratches or marks. However, stringent industry requirements often demand more sophisticated inspection methodologies to meet quality expectations.

Digital Surface Inspection Technologies

Advanced digital inspection tools such as profilometers, laser scanners, and digital microscopes offer precise, quantitative surface quality measurements. Such technologies deliver critical data to ensure compliance with industry standards and enhance confidence in product reliability and performance.

Common Challenges and Solutions for Achieving Flawless Finishes

Typical Defects and Their Causes

Typical defects encountered include spring-back, scratches, marks, and surface discoloration. These often originate from improper tool usage, inadequate bending settings, or the use of unsuitable materials.

Spring-back Issues: Managed by slight overbending or using predictive software simulations.

Cracking and Surface Defects: Addressed through controlled bending speeds, gradual methods, or appropriate heat treatments.

Implementing targeted solutions significantly reduces these issues, enhancing surface finish consistency.

Case Studies Highlighting Success in Surface Quality

Aerospace Industry Example

An aerospace company employing laser-assisted bending significantly reduced surface imperfections on titanium and special alloys. The precise control over heat application and bending force enabled compliance with stringent aerospace standards, thereby enhancing component lifespan and reliability.

Automotive Industry Example

A prominent automotive manufacturer integrated robotic CNC bending solutions, achieving consistent, high-quality surface finishes across mass-produced automotive frames and components. Automation dramatically reduced human error, minimized production cycle times, and improved overall product aesthetics and functionality.

Conclusion

Achieving flawless surface finishes in metal bending requires strategic investment in advanced technologies, precise tooling, optimal materials selection, and meticulous process management. By embracing CNC, laser-assisted, and robotic bending systems, combined with rigorous quality assurance methods, manufacturers can consistently deliver superior-quality products. These strategies strengthen market competitiveness and ensure sustained operational excellence and growth.

FAQs

What is CNC metal bending and how does it improve efficiency?

What types of metals can be effectively processed through metal bending operations?

How do automated metal bending solutions reduce production costs?

What are the common defects in custom metal bending and their solutions?

How does proper operator training impact the accuracy of metal bending operations?