Is over-molding suitable for both low and high-volume production?

Is Overmolding Suitable for Both Low and High-Volume Production?

Flexibility Across Production Scales

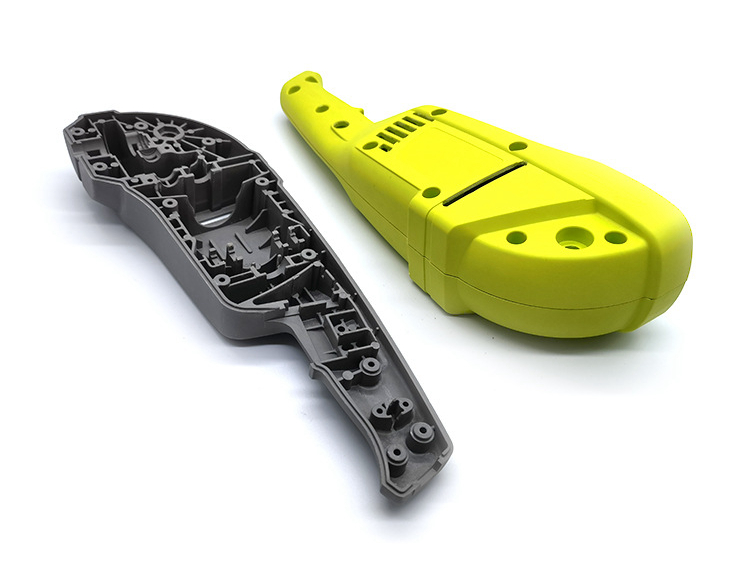

Yes — overmolding is highly adaptable and can be efficiently applied to both low- and high-volume production. Its versatility makes it a preferred process for industries ranging from consumer electronics to automotive and medical devices. The decision primarily depends on tooling strategy, part complexity, and the type of materials selected for both the substrate and overmold.

Low-Volume Production: Prototyping and Customization

For small batches or product development stages, overmolding is ideal when combined with rapid prototyping methods, such as rapid molding or 3D printing. These methods enable engineers to validate adhesion, ergonomics, and color performance prior to mass production. Low-volume runs also suit niche products or pilot batches that require frequent design iterations or material adjustments. Using plastic injection molding tools with interchangeable inserts helps reduce setup costs while maintaining precision.

High-Volume Production: Efficiency and Consistency

When scaling up, the advantages of overmolding multiply. With optimized tooling, automated feeding, and multi-cavity molds, high-volume runs deliver exceptional consistency and cycle efficiency. Durable thermoplastics such as polycarbonate (PC) and nylon (PA) serve as robust substrates, while thermoplastic elastomers (TPE) and TPU provide flexible, soft-touch finishes. In large-scale manufacturing, automation ensures repeatability and minimizes variation between parts.

Cost and Process Considerations

For low-volume production, tooling amortization can increase unit costs, but the benefits of design validation often outweigh the expense. In contrast, high-volume production capitalizes on the longevity of precision-built molds and lower per-part costs. Collaborating with an experienced custom parts manufacturing service ensures optimized mold design, material bonding, and production scalability.

Surface Finish and Post-Processing

Regardless of production scale, incorporating finishing processes such as polishing or in-mold decoration (IMD) can enhance the final product’s quality and market appeal, ensuring a professional and durable surface finish.