What products use overmolding?

Overmolding refers to molding one component over another pre-molded substrate using two consecutive injection molding operations. Overmolding combines two or more components' material properties and colors into a single part. It is used across many industries to manufacture diverse products. Some of the most common examples include:

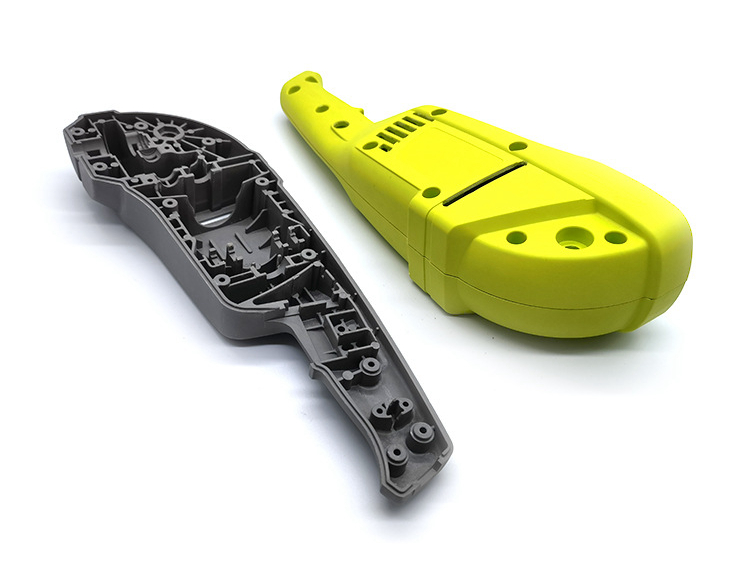

Power Tools

Power tools like electric drills, drivers, nail guns, saws, sanders, and routers frequently use overmolding. The rigid plastic housing and gearbox provide strength and structure, while the over-molded rubberized grip areas provide an ergonomic, non-slip hold and impact absorption. Overmolding also enables brightly colored accents for brand identity and visual appeals. The power cord is often over-molded with a thicker layer near the plug for strain relief and abrasion resistance.

Automotive Parts

Modern automotive interiors utilize over-molded components for aesthetic and functional purposes. Soft-touch elastomeric keypads are commonly over-molded onto more rigid plastic substrates on control panels and consoles. It provides a quality look and feel while facilitating the backlighting of the buttons and symbols. Interior trim pieces also use overmolding to combine materials and colors. Functional parts like seals, gaskets, bumpers, and shaft bearings are also frequently produced via overmolding.

Consumer Electronics

Protective outer cases and covers on smartphones, laptops, tablets, headphones, and other electronics are often over-molded onto the core rigid plastic housing for impact absorption and grip. The elastomeric material provides shock resistance if the device is dropped. The cases can also include anti-microbial additives to inhibit bacteria growth. Many connectors utilize overmolding to combine flexible cabling with hard plastic plug ends.

Medical Devices

Medical products like surgical power tools, therapy devices, and diagnostic equipment utilize overmolding for ergonomic grips, impact resistance, and seamless design. Handheld devices are over-molded with a textured elastomer for optimal grip and tactile feedback, even if the user is wearing gloves. Overmolding enables seamless one-piece construction for easy cleaning and sterilization with minimal crevices.

Sporting Goods

Sporting equipment like golf clubs, tennis and badminton rackets, hockey sticks, baseball bats, football helmets, and more use overmolding to apply soft, durable grips onto their rigid cores. It improves handling and control for users during athletic activities. Manufacturers brand their products by color-coordinating the grip and core components. Protective over molds are added onto frames and structural components for impact absorption.

Toys

Many toys are designed to enhance safety and appeal to children using overmolding. Brightly colored rubber is over-molded onto plastic parts to provide a soft, tactile surface less prone to scratching or injuring the child. Toys also use overmolding to produce multiple colored objects in one step for visual interest. Certain electronic learning toys feature push buttons over-molded onto the case to seal out dirt while enabling interactive lights and sounds.

Footwear

Shoe soles and other components are often fabricated using overmolding. The exterior rubber tread can be molded over a firmer interior plastic form for traction and abrasion resistance. Logos and decorative accents are also applied using layered overmolding techniques. Specific athletic shoes feature air cushions encapsulated within a secondary overmold layer for improved shock absorption.

Household Appliances

Kitchen appliances like microwaves, blenders, and mixers utilize over-molded parts for visual and haptic appeal and functionality. Control panels feature membrane switches and buttons over-molded with a colored silicone keypad. Appliance bodies include grip areas over-molded with rubber for easy handling. Interior components like baskets and beaters are co-molded from rigid and soft materials for durability and safety.

Lawn and Garden Equipment

Outdoor power tools need to withstand weather, dirt, and heavy use. Branding colors and tactile grips are often achieved by overmolding rubber onto the rigid plastic housing. Overmolding also enables applying thicker elastomers onto high-wear sections prone to abrasion when gardening. Many tool attachments utilize co-molding as well for performance and cosmetics.

Food Processing Equipment

Commercial food processing machinery uses overmolding for safety and longevity in demanding sanitary environments. Components like soft-grip control levers provide worker comfort and safety, while co-molded seals simplify cleaning procedures. Hard plastic blades can be over-molded with a softer thermoplastic tip to minimize damage if they make contact. Warning accents and labels are also often over-molded.

With the benefits of combining substrates, simplifying assemblies, and enabling ergonomics and protection, overmolding continues growing as a critical manufacturing process across virtually every industry. As the technology evolves, even more products will leverage overmolding to optimize performance, economics, and appeal.