What is overmolding, and how does it enhance durability?

What Is Overmolding, and How Does It Enhance Durability?

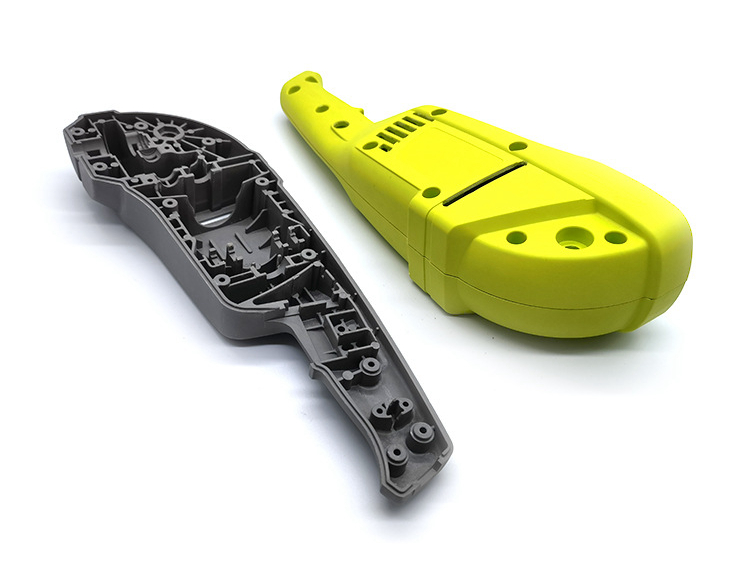

Overmolding is an advanced injection molding process where a second material is molded over a previously molded part, known as the substrate. The result is a multi-material component with enhanced structural, functional, or aesthetic properties. This technique is widely used in industries like automotive, medical devices, and consumer electronics to improve grip, shock resistance, and sealing performance.

How Overmolding Works

The process typically involves two stages:

Injection of the substrate – usually a rigid plastic such as ABS, PC, or Nylon.

Injection of the overmold layer – a softer material like TPE, TPU, or silicone is molded directly onto the substrate.

The two materials chemically or mechanically bond during the molding cycle, forming a durable, integrated component.

→ Learn more: Overmolding Services

Durability Enhancements Through Overmolding

1. Improved Impact and Shock Resistance

The soft overmold layer acts as a buffer, absorbing shocks and protecting the rigid core. This is essential in hand tools, mobile devices, and wearables exposed to frequent drops or vibration.

2. Enhanced Grip and Ergonomics

Materials like TPE and TPU provide a rubberized, non-slip surface that improves handling and reduces user fatigue in tools, medical instruments, and handheld electronics.

3. Superior Sealing and Water Resistance

Overmolding can create seamless seals around connectors, buttons, or enclosures, improving water and dust ingress protection (IP ratings) without additional gaskets or adhesives.

4. Reduced Assembly and Fastening

Because overmolding combines two materials in one mold cycle, it eliminates the need for secondary assembly, screws, or gluing—leading to stronger joints and fewer failure points.

5. Extended Service Life

The tight bond between substrate and overmold layer reduces wear and deformation over time, even in harsh environments involving chemicals, temperature swings, or mechanical stress.

Applications That Demand Overmolding Durability

Automotive: Grips, buttons, and dashboard components

Medical: Diagnostic device housings and handles

Consumer electronics: Shockproof phone cases, plugs, and wearable shells

Industrial: Overmolded seals and ergonomic machine components

Why Choose Neway for Overmolding Projects?

Neway Precision offers:

Overmolding of rigid-soft, metal-plastic, and plastic-plastic combinations

Tight tolerance control with ±0.01 mm precision

Fast lead times and scalable solutions for prototypes to mass production