What industries benefit most from overmolding techniques

What Industries Benefit Most from Overmolding Techniques?

Overmolding has become an essential technique for industries demanding performance, ergonomics, and product durability. By combining two or more materials—typically a rigid substrate with a soft, functional outer layer—overmolding enhances product functionality while reducing assembly complexity. This technique is particularly valuable in sectors where vibration resistance, waterproofing, grip, or biocompatibility are critical.

1. Automotive Industry

Overmolding supports lightweighting, improved weather resistance, and modular sealing in modern vehicles. It’s widely used for:

Overmolded seals and gaskets

Vibration-dampening mounts and bushings

Grips on knobs, handles, and shift levers

TPV or TPE overmolded components for IP-rated assemblies

Reduced fasteners through integrated design

Explore more: Automotive Solutions

2. Medical Devices

Precision and biocompatibility are essential in medical applications. Overmolding allows for:

Ergonomic, soft-touch grips on surgical tools

Biocompatible seals in diagnostic equipment

Sealed housings with smooth contours for easy sterilization

Insert-molded stainless steel + silicone handles

LSR (liquid silicone rubber) overmolding for implantable components

Explore more: Medical Device Solutions

3. Consumer Electronics

With increasing demand for miniaturized, shock-resistant, and waterproof devices, overmolding plays a key role in:

Soft-over-hard shells for wearables and smartwatches

Vibration-absorbing TPE enclosures

USB cables, connectors, and buttons

Sealed battery compartments

Improved aesthetics and user comfort

Explore more: Consumer Electronics Solutions

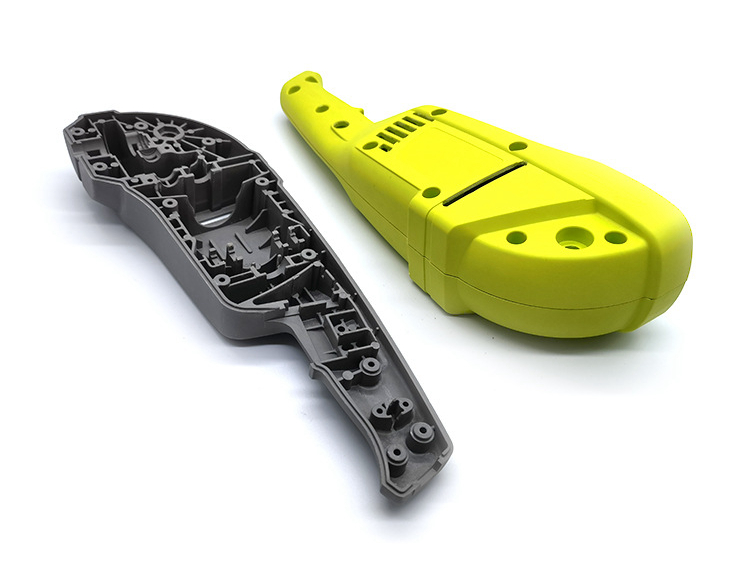

4. Power Tools and Industrial Equipment

Durability and comfort are key in industrial settings. Overmolding enhances:

Non-slip rubberized grips

Shock-resistant housings for drills and drivers

Overmolded trigger buttons and dials

Impact-resistant edge protection on heavy equipment

Dual-shot ergonomic handles

Explore more: Power Tools Industry Solutions

5. Telecommunication and Connectors

Overmolding ensures long-term performance in harsh environments:

Waterproofed connectors and housings

Strain-relieved cable entries

Molded-in shielding for EMI protection

Color-coded soft interfaces

Soft gaskets over rigid connectors

Explore more: Telecommunication Solutions

Why Choose Neway for Industry-Specific Overmolding?

Neway Precision provides:

Custom tooling for rigid-soft, plastic-metal combinations

±0.01 mm precision for complex assemblies

Material pairing validation and adhesion testing

Integrated design and prototyping via consultative engineering

Whether for IP-rated housings, soft-touch grips, or biocompatible assemblies, Neway helps you optimize overmolding for your application needs.