Are there any limitations or challenges associated with overmolding?

Are There Any Limitations or Challenges Associated with Overmolding?

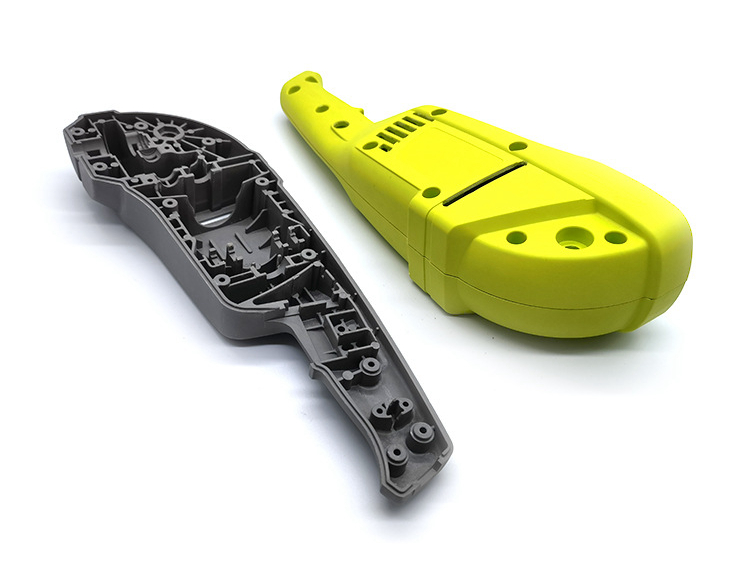

Yes—while overmolding offers many functional and aesthetic advantages, it also presents unique design, material, and manufacturing challenges. Understanding these limitations is essential for ensuring successful project outcomes, especially in applications that require high precision, structural integrity, or chemical resistance.

1. Material Compatibility

Challenge

Not all materials bond well with each other. Poor compatibility can lead to weak adhesion, delamination, or premature failure in use.

Examples

Polypropylene (PP) has low surface energy, requiring specially formulated TPEs or mechanical interlocks.

Some rigid plastics, like PBT or Nylon, may need surface treatments or primers.

Solution

Neway Precision performs material compatibility validation and offers guidance on adhesive vs. mechanical bonding strategies.

2. Tooling Complexity and Cost

Challenge

Overmolding typically requires multi-cavity molds or two-shot tooling, which are more complex and expensive than single-shot molds.

Solution

Early design for manufacturability (DFM) can reduce tooling complexity. Prototyping with simplified molds helps validate design before scaling.

3. Cycle Time and Process Control

Challenge

Because overmolding is a multi-step process, it increases cycle time and requires tight control over temperature, material flow, and positioning between shots.

Solution

Advanced automation and precision presses minimize variation. Neway’s integrated molding systems ensure second-shot alignment accuracy within ±0.02 mm.

4. Risk of Delamination or Warping

Challenge

If cooling rates or thermal expansion coefficients differ too much between materials, parts can warp or layers may separate under stress or over time.

Solution

Controlled temperature zones and precise mold design reduce these risks. Material shrinkage and flow analysis are conducted before mold fabrication.

5. Design Constraints

Challenge

Parts must be designed with specific overmolding considerations:

Draft angles for both shots

Proper venting

Bonding surface geometry

Avoiding sharp transitions or undercuts

Solution

Neway's team assists with optimized parting lines, radii, and wall thickness uniformity to prevent defects during second-shot molding.

6. Limited Repair or Rework Options

Challenge

Unlike assemblies with mechanical fasteners, overmolded parts are not easily repairable. A defect in one stage may render the entire component unusable.

Solution

Inline inspection and precision process control (e.g., vision systems, cavity pressure sensors) catch errors early in the cycle.

Why Partner with Neway?

Neway Precision helps mitigate overmolding risks by offering:

Precise material pairing validation

Tight-tolerance, multi-shot mold fabrication

Short-turn prototyping and bridge tooling

Full DFM consultation via engineering support