What types of materials can be processed using laser cutting?

What Types of Materials Can Be Processed Using Laser Cutting?

Metals

Laser cutting is widely used for processing both ferrous and non-ferrous metals with high precision and minimal material waste. Key materials include:

Stainless Steel: Thicknesses up to 25 mm can be cut with fiber lasers. Suitable for medical devices, automotive parts, and structural applications requiring corrosion resistance.

Carbon Steel: A cost-effective option for industrial components, often cut in thicknesses up to 30 mm. Common in sheet metal fabrication and machinery housings.

Aluminum Alloys: Reflective but effectively cut with high-power fiber lasers up to 15 mm. Common in aerospace, lighting, and enclosure systems.

Copper and Brass: Require precise beam control due to reflectivity, but are frequently used in electrical applications and busbar systems.

Non-Metals

Laser cutting is also effective on a wide range of non-metallic materials used in industrial and custom part production:

Plastics: Materials like acrylic (PMMA), polycarbonate, and ABS are cleanly cut for use in consumer electronics housings, displays, and signage.

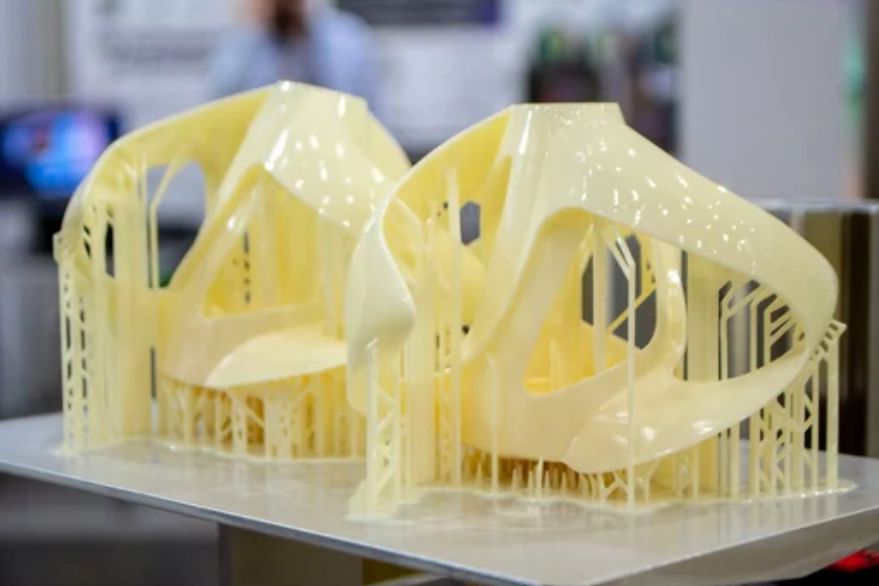

Wood: MDF, plywood, and hardwoods can be cut or engraved for furniture components and architectural models.

Rubber and Foam: Gaskets, seals, and padding materials are often laser cut to ensure tight tolerances and clean edges.

Textiles and Leather: Laser processing supports intricate patterns for fashion, automotive interiors, and industrial covers.

Composites and Specialty Materials

Advanced lasers can also process:

Carbon Fiber Composites: Used in aerospace and e-mobility, requiring careful thermal control.

Ceramics and Glass: Certain lasers (e.g., ultrashort-pulse lasers) can micro-machine hard, brittle materials for electronic or optical components.

Manufacturing Services for Laser-Cut Custom Parts

Neway provides precision laser cutting services for metals, plastics, composites, and specialty materials. With ±0.01 mm accuracy, advanced nesting software, and CNC machining integration, we deliver high-efficiency parts across global industries.