Which materials are most cost-effective for high-volume metal stamping?

Overview of Cost-Effective Materials for Stamping

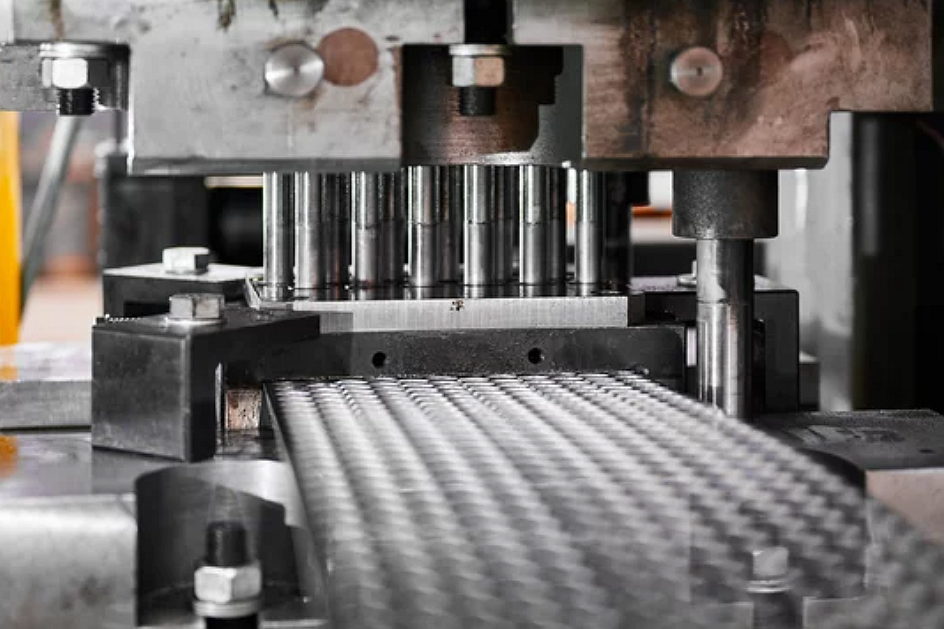

Selecting the right material for high-volume metal stamping requires balancing formability, cost, durability, and application-specific performance. In large-scale production, the most cost-effective options are those that provide stable stamping behavior, predictable tool life, and minimal waste. Manufacturers frequently validate stamping geometry early through prototyping or sheet metal fabrication before transitioning to full-scale tooling.

Progressive and transfer stamping operations often integrate upstream cutting methods, such as laser cutting or plasma cutting, with downstream forming, including metal bending or sheet metal stamping, to optimize cost and throughput.

Most Cost-Effective Metals for High-Volume Stamping

Carbon Steel

Carbon steel is among the most economical and widely used materials for stamping. Grades with moderate carbon content offer a good balance of strength and ductility. Its overall affordability and tool-friendly behavior make it suitable for industries such as automotive, where millions of components are produced annually. You can reference related alloys through carbon steel.

Stainless Steel

For applications requiring corrosion resistance and higher durability, stainless steel remains a stable and scalable option. While more expensive than low-carbon steel, it provides excellent lifecycle value. Material variations can be explored via stainless steel.

Copper Alloy

Copper alloys offer exceptional electrical and thermal conductivity, making them the preferred choice for telecommunication and consumer electronics. They stamp cleanly and exhibit low spring-back. Related details are available at copper alloy.

Cast Aluminum and Aluminum Alloys

Aluminum is lightweight, corrosion-resistant, and highly formable. It supports high-speed stamping while reducing tool wear. Low-density alloys used in sectors such as e-mobility facilitate large-batch production. Refer to common compositions, such as cast aluminum or die-casting grades like A380.

Zinc Alloy

Zinc alloys allow tight-tolerance stamping and excellent dimensional stability. Because they readily accept post-processing and plating, they are often selected for high-volume hardware and connector components. Details can be found at zinc alloy.

How Surface Finishing Impacts Material Cost-Effectiveness

Surface finishing adds downstream value, especially when selecting lower-cost base materials. Processes such as powder coating improve corrosion protection for carbon steel, while electroplating enhances conductivity and wear resistance for copper or zinc alloys. Choosing the right combination of material and finishing minimizes lifecycle cost without sacrificing performance.

Summary

Ultimately, carbon steel, aluminum, zinc alloy, stainless steel, and copper alloy represent the most cost-effective materials for high-volume stamping. Their stamping efficiency, availability, and predictable tool interaction make them ideal for continuous production environments.