How to balance cost, speed, and quality during prototyping?

Balancing cost, speed, and quality during prototyping requires a structured engineering approach that aligns material selection, manufacturing process, and part functionality to achieve optimal results. At Neway, we optimize this balance by selecting the most suitable prototyping route—whether CNC machining, 3D printing, or rapid molding—based on the design intent, geometry complexity, and validation goals.

Choosing the Right Process for Speed and Cost

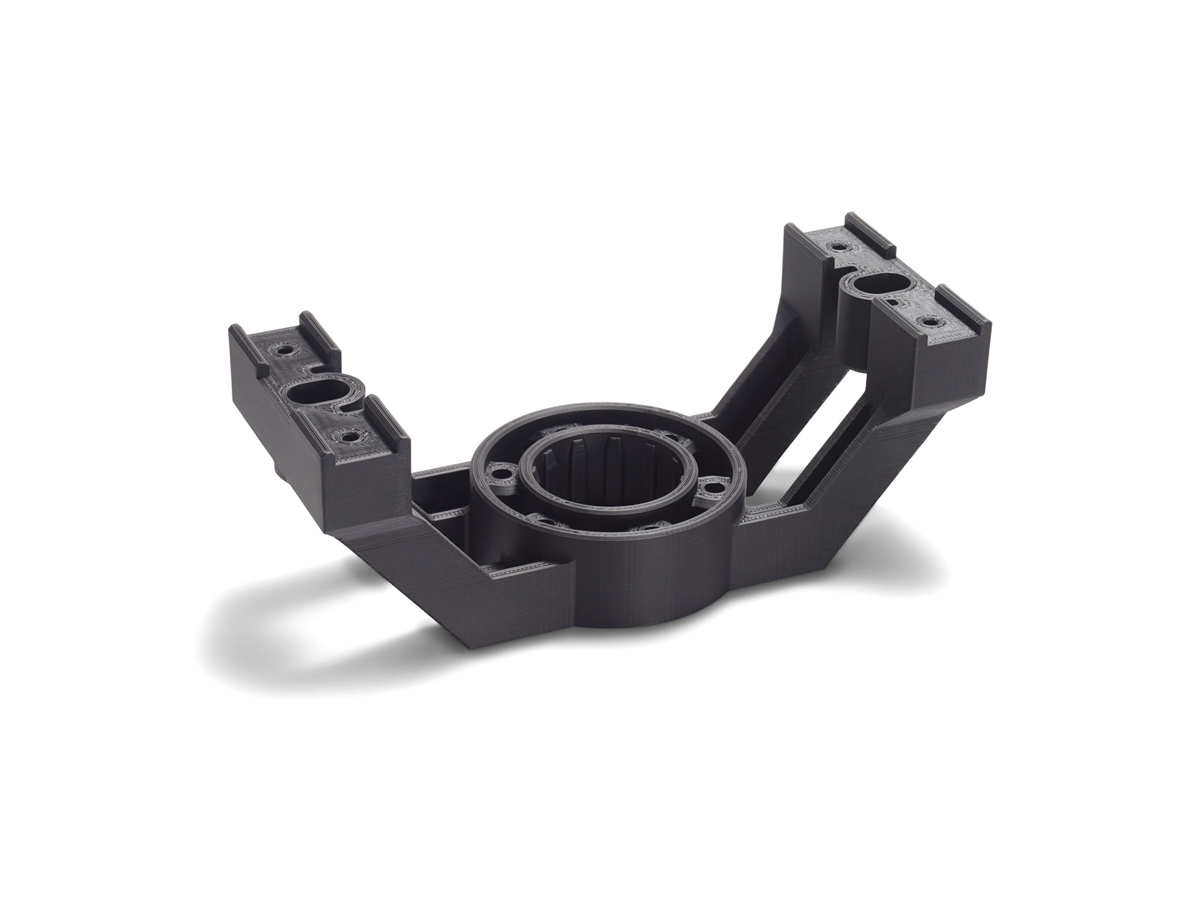

Early-stage prototypes benefit from fast-turnaround processes such as 3D printing prototyping, especially for complex internal structures, undercuts, or assemblies that require quick design iterations. 3D printing eliminates tooling costs and enables same-day revisions, making it ideal for proof-of-concept prototypes and ergonomic validation.

For functional prototypes that require higher mechanical strength or precise tolerances, CNC machining prototyping offers excellent dimensional accuracy and surface finish. Although machining may have a higher per-part cost compared to printing, it eliminates the risks associated with material anisotropy and provides more reliable performance feedback.

When transitioning into late-stage prototyping or low-volume bridge production, rapid molding prototyping becomes the most cost-effective option. It enables the testing of materials identical to those used in mass-production injection molding, while maintaining significantly lower tooling costs and shorter lead times compared to conventional molds.

Strategic Material Selection

Material choice greatly influences both cost and performance. Using engineering plastics such as ABS or PC-PBT is recommended for early prototypes due to affordability and ease of machining or printing. When thermal, mechanical, or chemical properties need to be validated, switching to production-grade materials—such as PEEK or zirconia — for high-performance applications ensures accuracy in functional testing.

For metal prototypes, aluminum alloys such as AlSi10Mg or cast aluminum offer an excellent balance between machinability, weight, and strength, enabling faster iteration without compromising quality.

Optimizing Quality With Controlled Post-Processing

Quality is enhanced through appropriate post-processing. Surface refinement methods, such as sandblasting, improve consistency for cosmetic evaluations, while precision-focused finishes, like an as-machined finish or polishing, ensure accurate mechanical testing. Functional prototypes may also require protective coatings, such as painting or PVD, to simulate final production conditions.

Engineering Practices to Balance All Three Factors

Simplify geometries during early design phases to reduce machining time and cost.

Utilize a modular design to facilitate individual component testing rather than testing complete assemblies.

Validate critical-to-function features early with CNC machining, while relying on 3D printing for non-critical geometries.

Align prototype goals: cosmetic evaluation, functional testing, or assembly verification—each requires different cost, speed, and quality priorities.

Plan an iterative prototyping schedule that shifts from fast/low-cost to high-fidelity/high-quality as the project progresses.