Custom Investment Cast Service

Precision investment cast solutions tailored to your needs. Experience exceptional quality, diverse material options, and reliable expertise for all your casting requirements.

- Materials: Materials: Materials: Materials: Materials: Materials: Materials: Materials: Materials: Materials:

- Size range: Min 10mm, Max 600 mm

- Tolerance: +/- 0.1mm

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Custom Investment Cast Service

Investment cast, also known as lost-wax casting or precision casting, is a metal casting process that involves injecting molten metal into a pre-made ceramic mold. The mold is then broken apart to reveal the solidified metal part.

- Precision and Accuracy: Our custom investment cast service ensures precise and accurate casting of complex shapes and intricate details, meeting your specific requirements.

- Versatile Material Options: We offer a wide range of materials, including stainless steel, aluminum, titanium, and more, allowing you to choose the best material for your application.

- Diverse Industries: Our investment casting service caters to various industries, such as aerospace, automotive, medical, and more, delivering solutions tailored to each industry's unique needs.

- State-of-the-Art Technology: With advanced equipment and cutting-edge technology, we utilize the latest techniques to ensure superior casting quality and efficiency.

- Prototyping to Production: From prototyping to large-scale production, our investment cast service covers the entire manufacturing process, providing seamless transition and consistent quality.

- Finishing Options: We offer a range of finishing options, including machining, polishing, plating, and coating, to meet your desired surface finish and appearance.

- Customization and Flexibility: We understand that every project is unique, and we provide customized solutions and flexibility to accommodate your specific design and production requirements.

Investment Casting Materials

Neway Custom Investment Casting Service Capabilities

Neway specialized in custom investment casting services for over 30 years. Typically Neway offers a range of capabilities to meet the needs of different industries and applications. Some of the most common capabilities include:Material Selection, Size and Complexity, Surface Finish

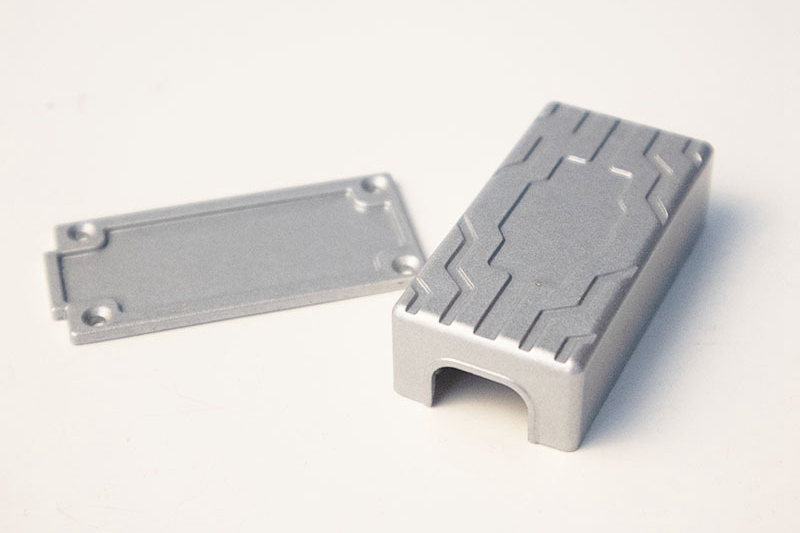

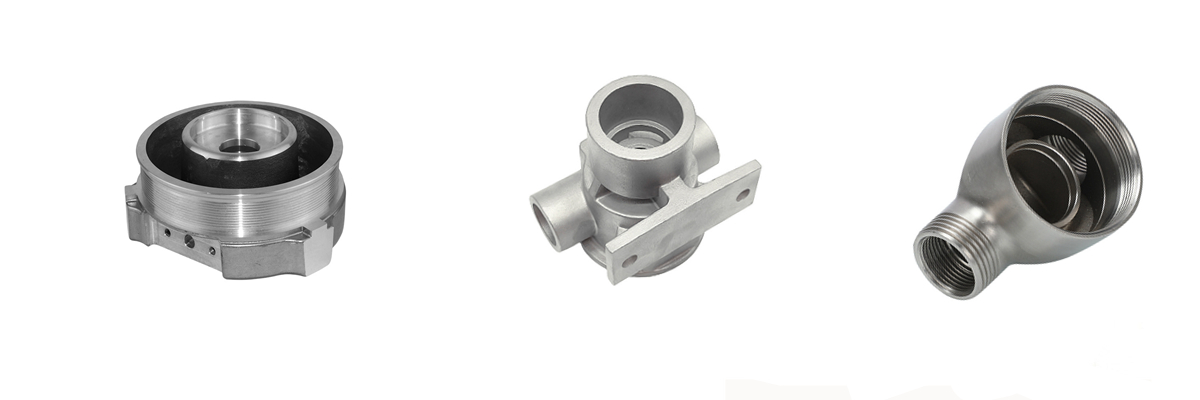

Custom Investment Parts Gallery

Explore our investment cast parts gallery and find out how diverse industries leverage their advantages.

Let's Start A New Project Today

Why Choose Us for Investment Cast Service

Casting in Zamak offers several advantages over other manufacturing processes and materials. Some of the main reasons why aluminum casting is a popular choice include:

Expertise

We have extensive experience and expertise in investment casting, enabling us to provide high-quality parts production services.

Technical Capability

We use advanced production technology and equipment to produce complex shapes and high-precision parts, ensuring product consistency and quality stability.

Material Selection

We offer a variety of metal and alloy materials to choose from, and we can select the most suitable materials based on customer needs.

Customer Service

We are committed to providing comprehensive services to our customers, from initial consultations to final delivery. We work closely with our customers to ensure their needs are met.

Custom Investment Casting Service Process Workflow

1

1

Mold CreationThe pattern is then used to create a mold, which is typically made of ceramic or plaster.

2

2

Wax InjectionMolten wax is injected into the mold, and then cooled to form a wax replica of the desired part.

3

3

AssemblyMultiple wax replicas are then assembled onto a wax sprue, forming a tree-like structure called a wax pattern.

4

4

Shell BuildingThe wax pattern is then coated with a ceramic shell, typically using a dipping process.

5

5

DewaxingThe ceramic shell is then heated, causing the wax to melt and run out of the mold, leaving a hollow cavity in the shape of the desired part.

6

6

PouringMolten metal is poured into the ceramic shell, filling the cavity and taking on the shape of the desired part.

7

7

FinishingThe cast part is then removed from the ceramic shell, and any excess material is removed using cutting or grinding tools. The part may also be polished or coated to achieve the desired surface finish.