Why is regular tooling maintenance critical in high-volume metal stamping processes?

Introduction

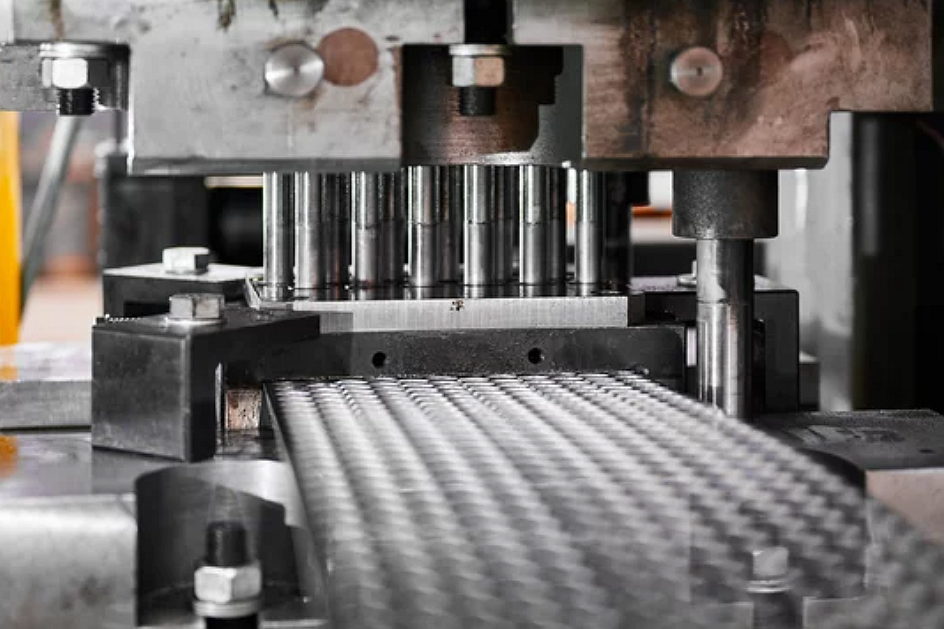

In high-volume metal stamping, tooling is the heart of the production process. Every punch, die, stripper plate, and guide surface experiences repeated high-force contact, making tooling maintenance essential to sustaining accuracy, efficiency, and part consistency. When supported by streamlined manufacturing processes such as sheet metal stamping, precise cutting operations like laser cutting, upstream forming processes including metal bending, and early design validation through prototyping or CNC machining prototyping, tooling maintenance ensures stable, long-term mass production.

How Tooling Maintenance Protects High-Volume Operations

Ensures Dimensional Accuracy

Progressive and transfer dies are responsible for producing thousands or millions of identical components. Even slight tool wear—whether on punches, forming radii, or trimming edges—results in dimensional drift. Using stable materials such as carbon steel, corrosion-resistant stainless steel, conductive copper alloys, lightweight cast aluminum, or engineered thermoplastics like ABS reduces forming unpredictability; however, maintaining a consistent tool condition is still critical to ensuring tolerance stability.

Reduces Scrap and Production Costs

Tool wear increases burr height, distortions, and rejected parts. In high-volume environments, even a slight increase in scrap rate can drastically increase costs. Regularly scheduled sharpening, alignment checks, lubrication, and punch replacement help maintain stable die performance. Industries such as automotive rely heavily on maintenance to avoid high scrap rates that can disrupt just-in-time production.

Protects Equipment and Extends Tool Life

A worn die creates abnormal loads on the press, feed mechanism, and guide posts. Without maintenance, this accelerates damage to not only tooling but also the stamping press itself. Real-time inspection and preventive maintenance extend equipment lifespan and ensure safe, continuous operation.

Improves Part Surface Quality

Surface defects such as scratches, galling, and drag marks often originate from worn or rough tool surfaces. When parts require cosmetic or functional finishing, consistent tooling is essential before applying treatments such as powder coating for durability or anodizing for corrosion protection. Poor tooling condition leads to poor coating adhesion and lower-quality finish results.

Ensures Reliability in High-Volume Industries

High-volume sectors such as consumer electronics require miniature, thin-gauge stamped components with extremely tight tolerances, where tool degradation immediately impacts assembly performance. In telecommunication, connector pins, shielding parts, and terminals rely on precision-cut edges and uniform geometry, which can only be delivered by well-maintained tools.

Conclusion

Regular tooling maintenance is crucial for high-volume stamping, as it stabilizes dimensional accuracy, reduces scrap, protects expensive equipment, maintains surface integrity, and ensures reliable production at scale. Combined with proper material selection, advanced finishing processes, and disciplined production monitoring, tooling maintenance is one of the most impactful cost-control and quality-control strategies in metal stamping.