What strategies help balance cost savings with quality assurance?

Introduction

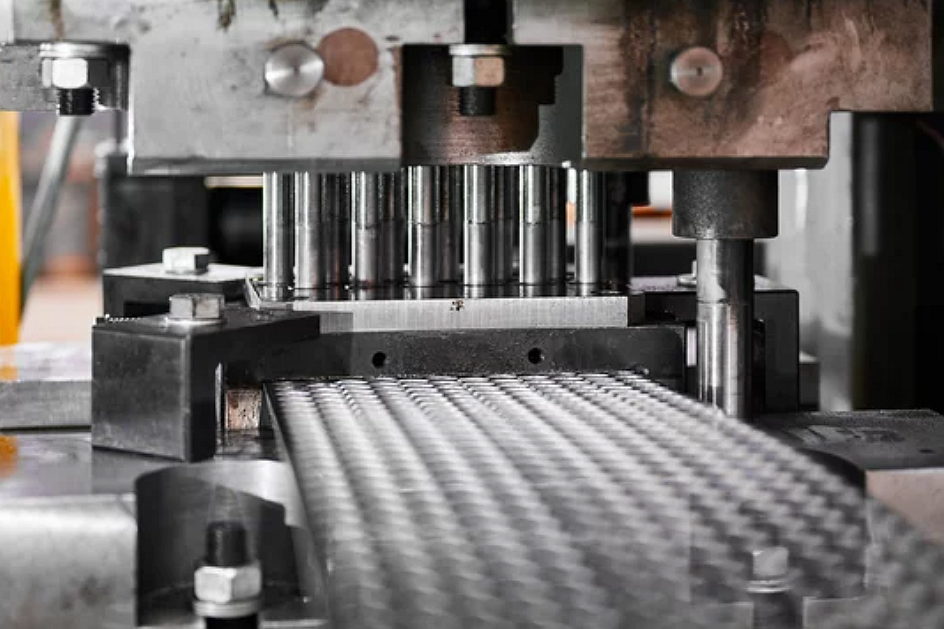

Balancing cost efficiency with consistently high product quality is a core challenge in metal stamping and precision manufacturing. Achieving this balance requires optimizing production flow, selecting the right materials and processes, and implementing sound design and validation strategies. Upstream fabrication methods, such as sheet metal fabrication and accurate cutting technologies like laser cutting, reduce initial variation and enhance repeatability. Integrated forming processes, including metal bending and robust sheet metal stamping, ensure stable dimensional performance. Early prototyping helps resolve design risks before scaling.

Key Strategies for Balancing Cost and Quality

1. Optimize Material Selection for Performance and Cost

Selecting the right alloy is one of the most direct ways to control both quality and cost. Materials such as stainless steel provide strength and corrosion resistance but may require higher forming forces. Cost-efficient metals like carbon steel lower raw material costs, while conductive alloys, such as copper alloys, ensure electrical performance in sensitive applications. Lightweight, formable options like cast aluminum and protective zinc alloy reduce the need for downstream finishing. Matching material attributes with functional needs prevents overengineering and unnecessary cost.

2. Implement Process Validation and Iterative Design

Rapid iterations before full tooling launch help minimize costly rework. Prototype validation plays a major role in achieving dimensional stability and eliminating defects early. Manufacturers can fine-tune design parameters, evaluate manufacturability, and validate forming behaviors before mass production begins.

3. Apply Automation for Consistency and Waste Reduction

Automated feeding, in-line monitoring, and robotic handling help standardize quality while lowering labor cost. Automation significantly reduces scrap—a major driver of cost—in high-volume sectors, such as the automotive industry and high-precision markets like telecommunications. In consumer electronics, automation ensures the accuracy of micro-features and functional reliability.

4. Use High-Quality Tooling with Predictive Maintenance

Investing in durable, properly treated dies reduces long-term maintenance cost. Predictive monitoring prevents excessive wear and avoids unplanned downtime. Optimizing lubrication, press alignment, and feed speed extends tool life while maintaining repeatability across large batches.

5. Reduce Secondary Finishing Through Controlled Forming

Well-controlled stamping processes minimize burr formation and surface defects, reducing the need for expensive secondary operations. When finishing is required, the strategic use of treatments such as anodizing or protective coatings, like powder coating, ensures durability without unnecessary steps.

Conclusion

Balancing cost savings with quality assurance requires coordinated improvements across material selection, process planning, automation, tooling management, and downstream finishing. By aligning manufacturing choices with functional requirements, companies achieve consistent quality and predictable cost performance across all production volumes.