What are the common issues encountered during mass production metal stamping

Introduction

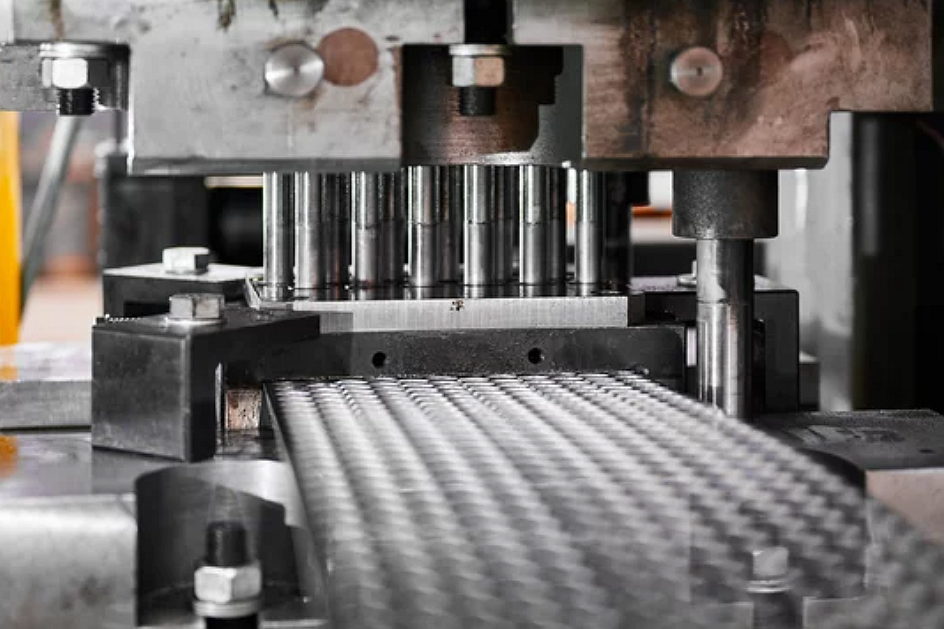

Mass-production metal stamping requires stable material behavior, precise tooling, and consistent feed control. When any factor becomes unstable, defects quickly multiply across large batches. Using reliable upstream and downstream processes such as sheet metal stamping, laser cutting, metal bending, prototyping, and CNC machining prototyping helps manufacturers validate part geometry before committing to full-scale production.

Common Issues in Mass Production Stamping

Material Inconsistency

Variations in material thickness, hardness, or grain orientation often result in cracking, wrinkles, or dimensional deviations. Selecting stable materials such as carbon steel, corrosion-resistant stainless steel, thermally conductive copper alloy, lightweight cast aluminum, or engineering plastics like ABS reduces unpredictability during forming.

Tool Wear and Alignment Problems

High-speed repetitive operations wear down punches, dies, and guide posts. Misalignment causes burrs, shape distortion, and accelerated tool damage. Preventive maintenance, periodic die regrinding, and proper lubrication are essential to ensure long-term stability, especially in fast-moving sectors such as automotive, where tooling performance directly affects cycle time.

Spring-Back and Dimensional Variation

Certain materials naturally rebound after forming. Aluminum and high-strength steels tend to exhibit higher spring-back, causing angle deviations and poor fit during assembly. Early-stage forming simulation combined with real-world validation through prototyping prevents costly die revisions later in production.

Feed System Errors

Incorrect coil feeding, slippage, or tension variations lead to mis-punched features or jammed dies. Automated coil feeders and optical monitoring greatly reduce these risks. Industries such as consumer electronics rely on tight-tolerance micro-stamped components, making consistent feed control essential.

Surface Defects

Scratches, scale marks, and tool drag marks are common, especially on softer alloys. Post-processing treatments such as powder coating help improve durability for functional parts, while electropolishing produces clean, smooth surfaces for components used in telecommunication equipment.

Excessive Burr Formation

Burrs occur when tools dull or material fractures irregularly. Maintaining proper cutting clearance and implementing timely punch replacement minimizes burr height. For aesthetic or safety-critical assemblies, secondary deburring processes may also be required.

Preventive Strategies for Stable Mass Production

A structured combination of material validation, robust die design, controlled feeding systems, precise press tuning, and consistent maintenance ensures stable stamping performance. Early prototyping reduces tooling risks and makes mass production more predictable. With the right combination of materials, stamping processes, and finishing controls, manufacturers can achieve a stable yield even in demanding high-volume applications.