How does material selection influence the economics of metal stamping?

Introduction

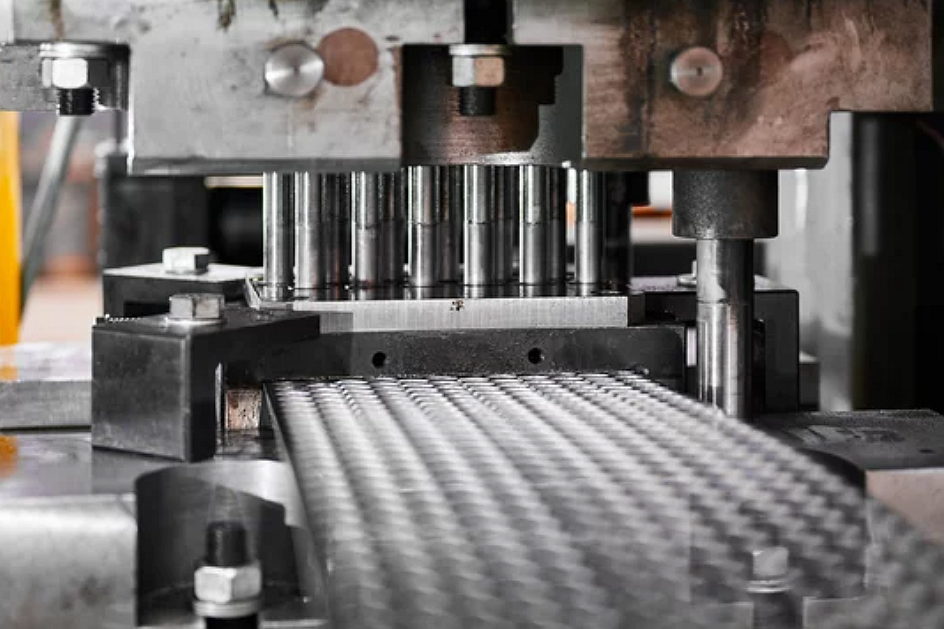

Material selection plays a central role in determining the total cost structure of metal stamping. The chosen alloy impacts tool wear, press tonnage, cycle time, scrap rate, and downstream finishing requirements. Before the stamping stage, upstream fabrication steps such as sheet metal fabrication and precision cutting processes like laser cutting help define raw material utilization. Additional forming methods including metal bending and efficiency-driven sheet metal stamping influence how each material behaves under load. Early part trials using prototyping ensure the selected metal supports manufacturability without unnecessary cost.

Impact of Material Properties on Cost

Formability and Tool Wear

Harder and more abrasive alloys increase die wear, directly raising tooling and maintenance costs. Materials such as stainless steel are more challenging to stamp, requiring stronger tool steels and more frequent sharpening. Cost-effective options such as carbon steel are easier to form and reduce tooling stress. High-ductility metals like copper alloys stamp easily but come with higher raw material pricing, shifting the cost from tooling toward material.

Strength and Thickness Optimization

High-strength alloys often require increased press tonnage and slower forming speeds, which raises operational cost. Aluminum materials such as cast aluminum reduce part weight and can enable faster cycles, but they require careful handling to avoid cracking. Materials with inherent corrosion resistance, such as zinc alloy, may reduce the need for additional protective finishing, thereby improving overall economics.

Industry-Driven Material Requirements

Different industries prioritize different performance-to-cost trade-offs.

The automotive sector balances material cost with strength requirements for brackets, mounts, and structural components.

Consumer electronics demand lightweight stamped housings and EMI-shielding parts, making aluminum and copper alloys common despite higher prices.

The telecommunication industry relies on precision metals that maintain conductivity and dimensional stability.

Influence on Finishing and Post-Processing

Material behavior also defines whether surface finishing is required. Alloys that oxidize quickly may need treatments such as anodizing or durability-enhancing coatings, such as powder coating. Materials with natural protective characteristics help eliminate these steps, reducing overall part cost.

Balancing Performance and Economics

For cost-effective stamping, manufacturers must balance material price, formability, tool life, and product requirements. A lower-cost alloy may increase scrap rate or reduce precision, while a higher-grade alloy may significantly increase tooling costs. The optimal choice ensures stable production efficiency, predictable tool life, and minimized post-processing.