How to choose a cost-effective manufacturing process for my sheet metal bracket prototype?

Evaluating the Requirements of Your Sheet Metal Bracket

Selecting a cost-effective process begins by understanding geometry, load conditions, quantity, and timeline. At Neway, early evaluation typically uses fast-turn prototyping services to determine whether cutting, forming, stamping, or hybrid routes deliver the lowest cost per part. For brackets with simple contours and uniform thickness, laser cutting offers high precision with minimal setup cost. When thicker materials or structural needs are involved, CNC machining prototyping may support tight tolerances for mounting interfaces, even if the part is primarily sheet-metal based.

Manufacturing Process Options and Cost Impact

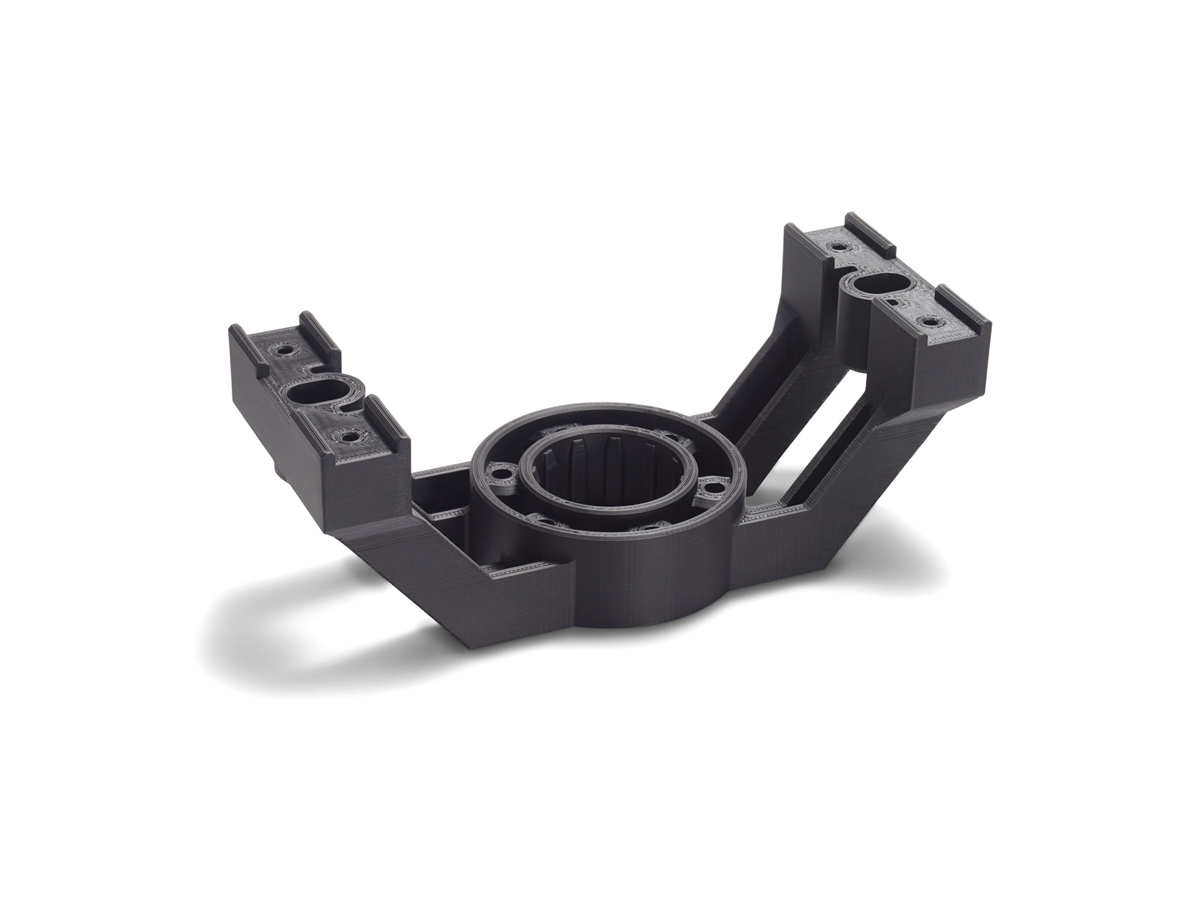

Flat-pattern brackets with moderate complexity are efficiently produced through sheet metal fabrication, enabling fast bending, punching, and forming without the need for dedicated tooling. For prototypes that require high repeatability, metal bending offers excellent dimensional accuracy at a low production cost. If the bracket includes multiple features requiring deformation or holes, sheet metal stamping can be used for larger batches, though it becomes economical only when volumes justify tool fabrication. For assemblies that require integrated inserts or structural reinforcement, insert molding can be used to combine metal skeletons with molded plastic sections in a single step.

Material Selection for Cost-Effective Prototyping

Choosing the right material has a major impact on cost. For general structural brackets, carbon steel offers excellent strength at the lowest material price. Corrosion-resistant prototypes, particularly for automotive or telecommunications modules, often utilize cast stainless steel, which strikes a balance between durability and moderate cost. Lightweight assemblies—especially in battery trays and EV platforms—benefit from 6000 series aluminum or AlSi7Mg when weight reduction is a priority. For high-heat environments or shielding brackets, specialized materials such as copper alloy or AlSi10Mg offer thermal performance while remaining cost-effective for prototypes.

Surface Treatments that Balance Cost and Functionality

For functional testing, an as-machined finish is often sufficient, eliminating extra cost while preserving tolerance accuracy. Brackets exposed to vibration, humidity, or salt spray can be protected using a durable painting process that minimizes corrosion without requiring unnecessary polishing or plating. These finishing selections ensure the prototype behaves like the final production part while keeping the budget under control.

Industry Considerations and Cost-Driven Priorities

In the automotive sector, brackets must fit tight tolerances for chassis, interior, or engine-bay interfaces, so CNC secondary machining may be prioritized over forming-only routes. For telecommunication equipment, EMI or thermal demands influence whether a conductive or lightweight material is used. In power tools, the balance between impact resistance and material cost determines whether steel or aluminum is preferable. Understanding industry-specific failure modes helps avoid over-engineering, keeping prototypes affordable while maintaining their function.