How does Neway ensure smooth transition from prototype to mass production?

Neway ensures a seamless transition from prototype to mass production by integrating engineering validation, process optimization, and material consistency across every stage of development. Whether a project begins with 3D printing, CNC machining, or rapid molding prototyping, our workflow is designed to progressively align prototype characteristics with full-scale manufacturing conditions. This structured approach minimizes redesign delays, reduces production risks, and ensures manufacturability before entering high-volume fabrication.

Design Validation and DFM Optimization

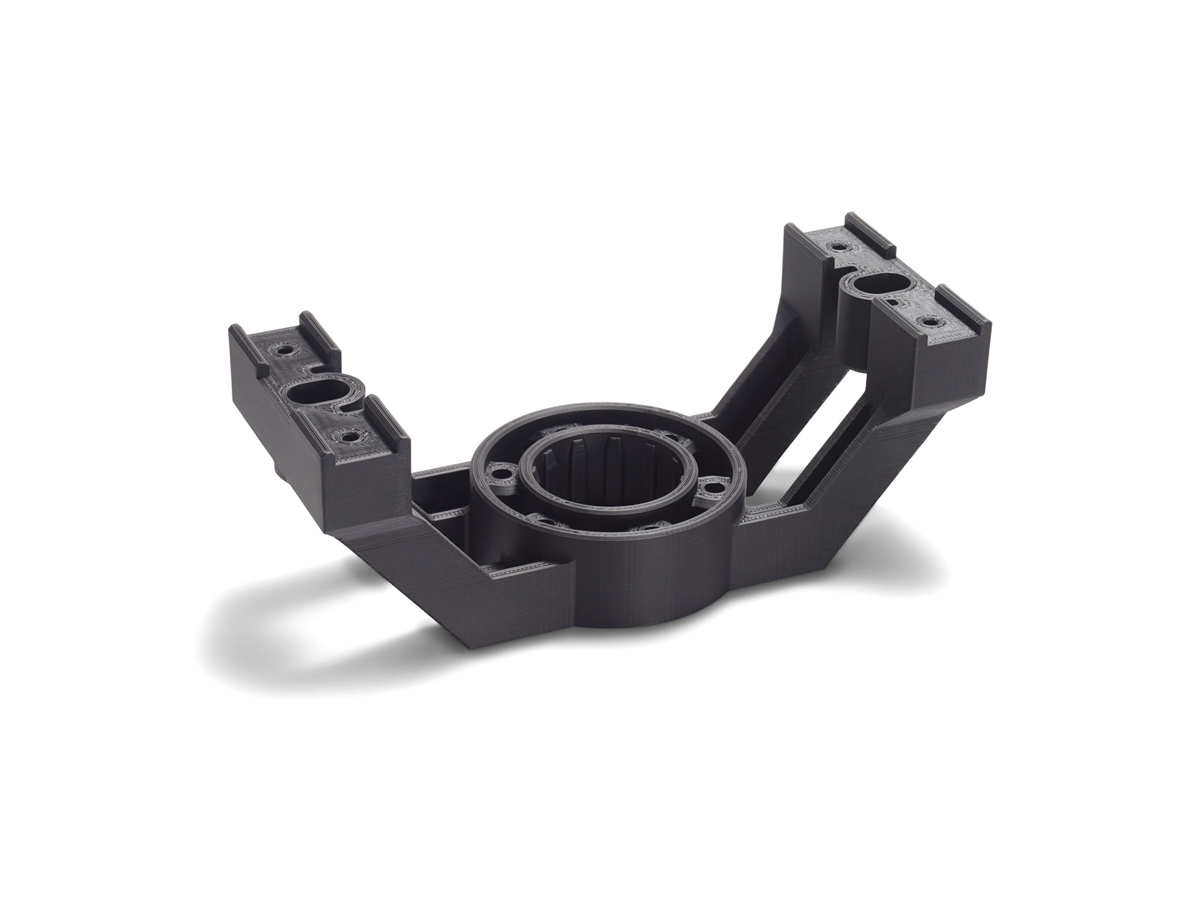

In the early prototype stage, Neway performs detailed Design for Manufacturability (DFM) reviews to identify potential issues in geometry, draft angles, tolerances, wall thickness, and assembly constraints. These evaluations ensure that the design is compatible with the chosen production process—whether it is injection molding, precision casting, aluminum die casting, or sheet metal fabrication. Early intervention significantly reduces costly changes once tooling begins.

Prototypes built with production-intent materials—such as ABS, PC-PBT, PEEK, cast aluminum, or AlSi10Mg—allow engineers to accurately assess performance and manufacturability before tooling investment.

Tooling Preparation and Process Simulation

Once the prototype is validated, Neway prepares low-risk tooling strategies using temporary or rapid molds to verify part flow, shrinkage behavior, dimensional repeatability, and assembly fit. For injection molding projects, this includes mold-flow simulation and gate optimization to ensure stable production. For metal parts produced via investment casting or sand casting, simulation is applied to analyze filling, solidification, porosity formation, and cooling behavior.

Through iterative mold trials, our engineers refine parameters such as injection pressure, holding time, cooling time, or casting temperature, ensuring consistent part quality before scaling to multi-cavity or hardened steel tooling.

Material Consistency and Post-Processing Alignment

Neway ensures material consistency between prototype and production by using the same or equivalent grades throughout the development cycle. This includes plastics such as nylon (PA) or polycarbonate, as well as metals like A380 aluminum or cast stainless steel. Consistency ensures test results remain valid when transitioning into full-scale production.

Post-processing steps—such as sandblasting, as-machined finishing, anodizing, or PVD coating—are also validated during prototyping to ensure consistent performance and appearance during mass production.

Pilot Production and Quality Assurance

Before full-scale manufacturing, Neway conducts pilot runs to verify process stability, yield rate, and repeatability. Dimensional inspection is conducted using CMM, optical measurement tools, and functional testing equipment to ensure that parts meet engineering specifications. Process capability studies (Cp/Cpk), statistical sampling, and control plans are implemented to establish quality baselines for mass production.

For industries requiring strict compliance—such as medical devices, aerospace, or automotive—Neway documents traceability, inspection standards, and validation procedures for seamless regulatory alignment.

Full Production Launch

Once all parameters are validated, Neway transitions to full-scale manufacturing using optimized tooling, stable process settings, and verified production workflows. Our custom parts manufacturing service ensures consistent output across machining, molding, casting, and sheet-metal processes. Continuous feedback loops and early batch inspections maintain quality throughout the lifecycle.