Which prototyping method suits complex electronic housings?

Best Prototyping Methods for Complex Electronic Housings

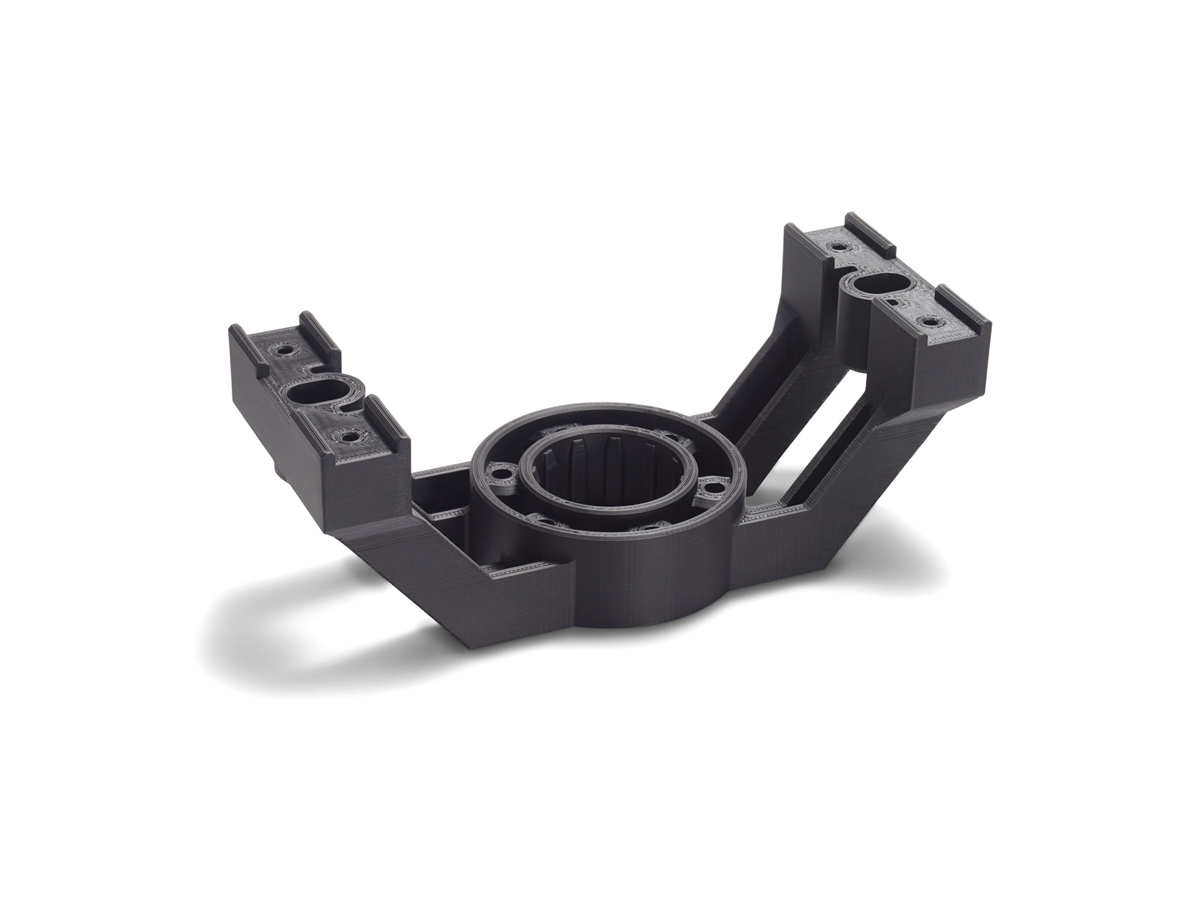

Complex electronic housings typically involve multi-surface geometries, thin walls, precise snap-fits, internal mounting features, and cosmetic surface requirements. Selecting the right prototyping route depends on whether the goal is functional verification, aesthetic validation, or preparing for mass-production tooling. At Neway, electronic enclosure projects usually begin with prototyping to confirm structural integrity, assembly fit, and user-facing appearance before moving into full production.

Recommended Methods by Functional Need

Method | Benefits | Best Used For |

|---|---|---|

High dimensional accuracy, excellent surface quality, stable thin-wall performance, ideal for engineering plastics. | • Structural integrity checks • Snap-fit tuning • Cosmetic evaluation for painting/anodizing • Polycarbonate, ABS, PEEK, or aluminum housings | |

Fastest way to validate geometry. Supports complex internal cavities and ergonomic design tests. | • Early-stage form validation • Complex internal ducting • Quick iterations for UI/UX housing concepts | |

Soft tooling produces near-production plastic housings with real textures, gate marks, draft effects, and warpage behavior. | • Production-quality appearance • Texture validation (VDI/MT) • Functional assemblies with multi-parts • High-end consumer electronics and IoT devices | |

Overmolding trial builds | Useful when housings require dual-material interfaces, soft-touch zones, or waterproof sealing structures. | • Handheld devices • Wearables • Ruggedized housings with TPE/TPU layers |

Material Considerations for Housing Prototypes

Electronic enclosures rely heavily on engineering polymers due to strength, cosmetic performance, and moldability. CNC and rapid molding support commonly used materials such as ABS, PC, PC-PBT, and PEEK. For premium outward appearance, overmolding and painting are often validated using CNC samples first, then transferred to mold-based prototypes.

Surface Finish Validation

Complex housings often require high-end finishing. CNC prototypes allow early evaluation of textures, radii, and surface transitions prior to applying painting, PVD coatings, or anodizing for metal housings. Rapid-molded parts offer the closest match to final cosmetic conditions including gloss levels, texture depth, and gate visibility.

Which Method to Choose?

• If **speed** is the priority → choose 3D printing. • If **precision and structural realism** are needed → choose CNC machining. • If **near-production quality** is required → choose rapid molding. • If **multi-material or sealing design** is involved → use overmolding trials.