What are the best materials to use in Over Molding for aesthetic purposes?

Understanding Aesthetic Overmolding

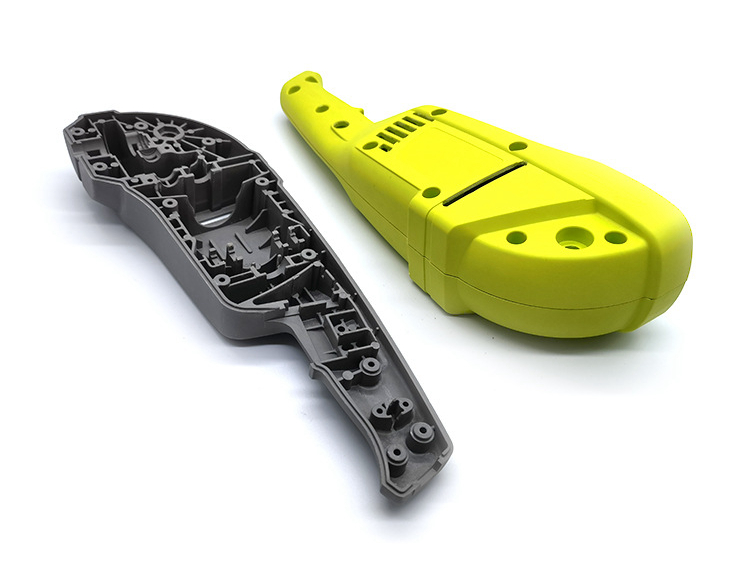

In aesthetic-driven product design, overmolding is a key process that blends visual appeal with ergonomic comfort. It allows designers to combine multiple materials in a single molded component—typically a rigid substrate and a soft outer layer—to create both functional and visually refined products. Industries such as consumer electronics and medical devices rely on this process to improve tactile experience, grip, and overall brand perception.

Ideal Base Materials for Overmolding

For the substrate, materials like polycarbonate (PC), nylon (PA), and ABS are popular due to their rigidity, impact resistance, and excellent surface finish. These thermoplastics form strong mechanical bonds with elastomers, maintaining precise dimensional stability during molding, and ensuring that the outer layer adheres seamlessly.

When aesthetic clarity or transparency is desired—such as in LED housings or cosmetic covers—materials like acrylic (PMMA) or polycarbonate blends (PC-PBT) offer high optical quality and color versatility.

Soft Layer Materials for Visual and Tactile Appeal

The soft overmold layer defines the part’s visual identity and feel. Thermoplastic elastomers (TPE) and TPU are the leading choices due to their flexibility, smooth surfaces, and ability to be colored or textured. In applications requiring a premium, skin-safe finish—such as wearable devices or medical grips—silicone rubber provides exceptional softness and visual uniformity.

To enhance surface luster or add branding effects, secondary finishing such as in-mold decoration (IMD) and polishing can be applied directly during or after molding. These treatments enable designers to create consistent textures and gloss levels throughout the entire part, thereby elevating the perceived quality.

Combining Aesthetics with Performance

Choosing the right combination of substrate and elastomer ensures not only a striking appearance but also long-term performance. Factors like adhesion compatibility, thermal resistance, and mold flow should always guide material pairing. Collaborating with a custom parts manufacturer experienced in overmolding can help achieve precise color matching, surface uniformity, and ergonomic comfort—all while maintaining structural reliability.