What types of materials can be effectively used in over-molding?

What Types of Materials Can Be Effectively Used in Overmolding?

The Foundation of Multi-Material Integration

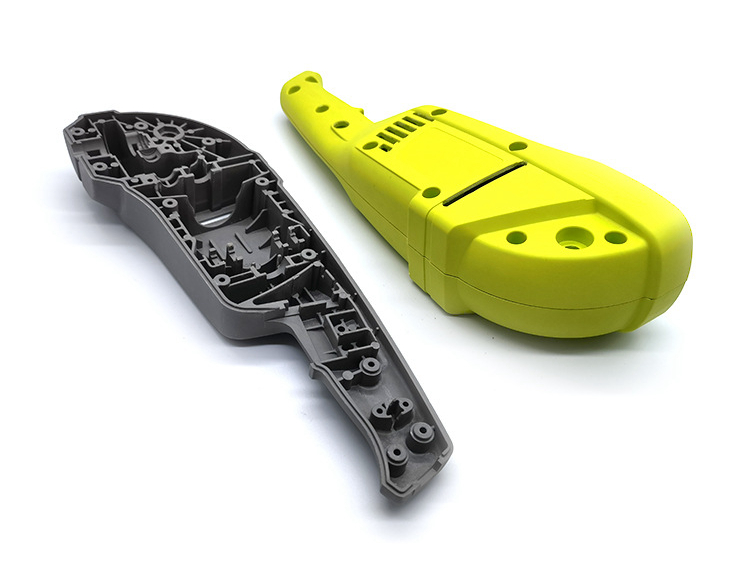

Overmolding enables manufacturers to combine two or more materials into a single, unified component—typically a rigid substrate paired with a softer overmold. This technique enhances grip, durability, and visual appeal while reducing the number of assembly steps. The key to success lies in selecting materials that bond well during the molding process and maintain dimensional stability throughout their service life.

Common Substrate (Base) Materials

The base layer provides the structural strength and is usually made from engineering-grade thermoplastics. Popular choices include ABS for cost-effective rigidity, polycarbonate (PC) for impact resistance, and nylon (PA) for excellent toughness and wear resistance. In high-performance products, such as automotive components and medical devices, substrates like PBT and PPS are utilized for their dimensional stability and chemical resistance.

Overmold (Soft Layer) Materials

The soft layer adds comfort, protection, and aesthetic value. Thermoplastic elastomers (TPEs) are the most versatile choice because they bond well with many rigid plastics and can be easily colored or textured. TPU is favored for its toughness and resistance to abrasion, while silicone rubber is ideal for applications requiring flexibility, softness, and biocompatibility—such as handles, grips, or wearable devices.

Metal and Ceramic Substrates

For hybrid products where strength or conductivity is essential, metal components manufactured via precision casting or CNC machining prototyping can serve as the substrate. The overmolded elastomer protects metal surfaces from corrosion and enhances ergonomics. Even ceramic parts created through ceramic injection molding (CIM) can be selectively overmolded when thermal and dielectric performance are critical.

Enhancing Material Compatibility

Successful overmolding depends on temperature and chemical compatibility between the substrate and overmold. Engineers often apply adhesion promoters or use mechanical interlocks in mold design to ensure reliable bonding. Combining these materials within a custom parts manufacturing service environment ensures optimal adhesion, repeatability, and surface finish.