Can Over Molding help improve product durability?

The Role of Overmolding in Enhancing Durability

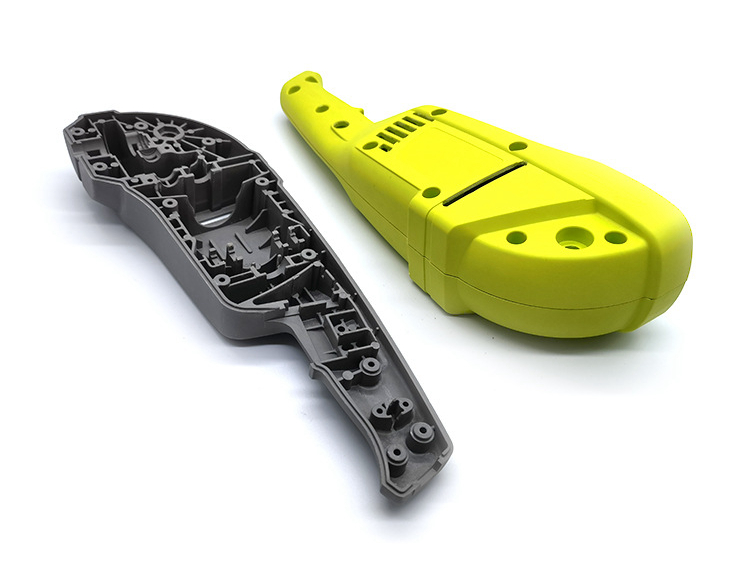

Yes — overmolding can significantly improve product durability by combining the mechanical strength of rigid plastics with the protective flexibility of elastomers. This hybrid molding approach not only enhances a product’s lifespan but also maintains its visual appeal under harsh operating conditions. In sectors like automotive, power tools, and consumer electronics, overmolding is frequently used to reinforce parts that experience impact, vibration, and frequent handling.

Strength from the Base Material

The core substrate in overmolding serves as the foundation for structural integrity. Materials such as nylon (PA), polycarbonate (PC), and ABS offer excellent dimensional stability, tensile strength, and resistance to cracking. These materials are particularly valuable in applications where rigidity and impact resistance are critical—such as housings, enclosures, and brackets.

Protective Function of the Overmold Layer

The overmold layer—commonly made from thermoplastic elastomers (TPE), TPU, or silicone rubber—acts as a shock absorber and environmental shield. It reduces mechanical stress on the substrate and protects against abrasion, chemical exposure, and moisture ingress. In hand tools or electronic casings, this layer also prevents slippage, ensuring a secure grip even under demanding use conditions.

Surface Treatment for Extended Lifespan

Beyond material selection, surface finishing enhances longevity and protection. Powder coating or PVD coatings can be applied to metal or plastic components to improve wear resistance and prevent corrosion. Similarly, heat treatment processes for metallic inserts can further strengthen the core before overmolding, resulting in a product that can endure both physical and thermal stresses.

Precision Manufacturing for Long-Term Reliability

Partnering with a custom parts manufacturing service that integrates plastic injection molding and overmolding ensures consistent bonding and tight dimensional tolerances. This synergy between precision engineering and material science ultimately delivers components that maintain function and finish even after prolonged use in industrial or consumer environments.