What types of products benefit most from Over Molding?

Enhancing Functionality and Aesthetics

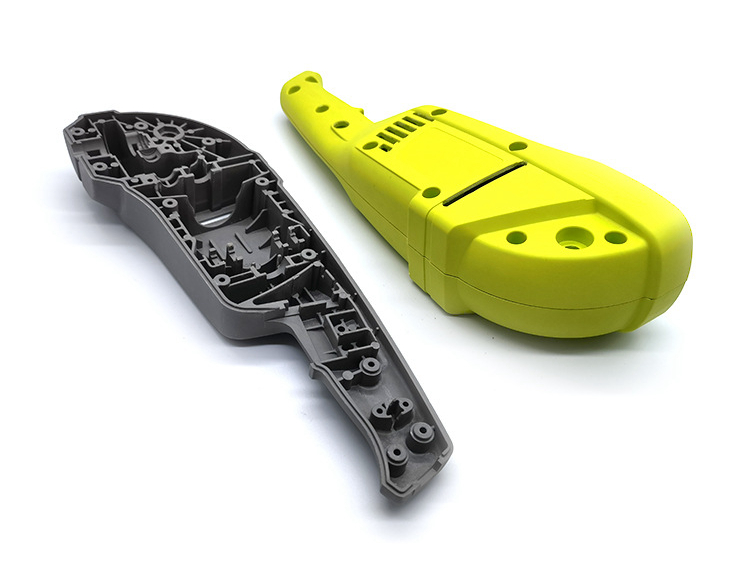

Overmolding is ideal for products that require a balance between functionality, comfort, and visual appeal. By combining different materials through the overmolding process, manufacturers can produce multi-material components that improve grip, insulation, and overall durability. This process is particularly effective for consumer products where tactile comfort and ergonomic design are essential.

Applications in Key Industries

In the automotive industry, overmolding enhances interior and exterior components, including control knobs, switches, and sealing systems. The combination of rigid substrates, such as nylon (PA), with soft elastomers, like TPE-TPV, offers vibration damping and a superior tactile feel.

For medical devices, overmolding offers chemical resistance and biocompatibility, making it ideal for surgical handles and housings that require both hygiene and comfort.

In consumer electronics, the process enables the creation of slim, durable enclosures and waterproof sealing for wearable devices and handheld tools.

Materials and Process Integration

Overmolding often works in tandem with injection molding and insert molding to streamline production. Compatible thermoplastics such as ABS-PC or polycarbonate (PC) ensure strong bonding and mechanical stability.

Advancing Product Performance

Overmolded parts are also prevalent in power tools and industrial equipment, where the soft layer reduces fatigue and enhances control. These advantages make overmolding indispensable for achieving long-term durability and user satisfaction in precision-engineered products.