How much cost reduction can manufacturers typically expect from implementing over-molding?

Understanding Overmolding’s Economic Advantage

Implementing overmolding can reduce total manufacturing costs by 15% to 40%, depending on part geometry, materials, and production volume. While the tooling investment may initially appear higher than that of traditional single-shot molding, the long-term benefits—such as fewer assembly steps, reduced labor, and improved product reliability—often result in substantial savings over the product's lifecycle.

Reduction in Assembly and Labor Costs

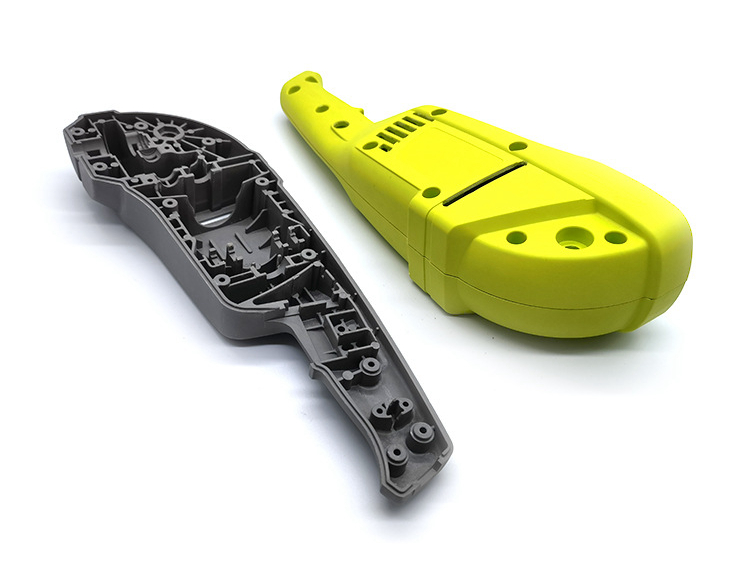

A major cost advantage of overmolding lies in process integration. By combining multiple materials—like a rigid polycarbonate (PC) substrate and a soft thermoplastic elastomer (TPE) layer—into one molded component, manufacturers eliminate secondary bonding, fasteners, or adhesives. This reduces manual assembly time and the risk of human error, which in high-volume production can translate into thousands of hours saved annually.

Lower Material Waste and Inventory Complexity

Because plastic injection molding precisely meters material usage, waste rates are significantly lower than in traditional multi-part assembly. Using durable polymers such as nylon (PA) and ABS also minimizes rework and rejects caused by poor fit or deformation. The ability to consolidate parts into a single overmolded piece simplifies logistics and reduces the need to manage multiple SKUs or storage bins for different components.

Enhanced Product Lifespan: Reducing Replacement Costs

Overmolding enhances a product’s durability by providing improved bonding, enhanced vibration resistance, and enhanced sealing performance. This results in fewer warranty claims and longer product lifespans, particularly in demanding applications such as automotive components, power tools, and medical devices. When combined with finishing methods like PVD coating or powder coating, overmolded parts maintain aesthetic quality and functionality longer, reducing maintenance and replacement expenses.

Cost Optimization Through Prototyping and Scaling

Partnering with a custom parts manufacturing service enables cost-efficient scaling. Early-stage rapid molding prototyping helps refine designs, optimize mold flow, and prevent costly redesigns before high-volume production. Once scaled, the automation of multi-shot systems ensures consistent cycle times and further lowers per-unit cost.