How does Over Molding enhance ergonomic design?

The Role of Material Integration in Comfort and Control

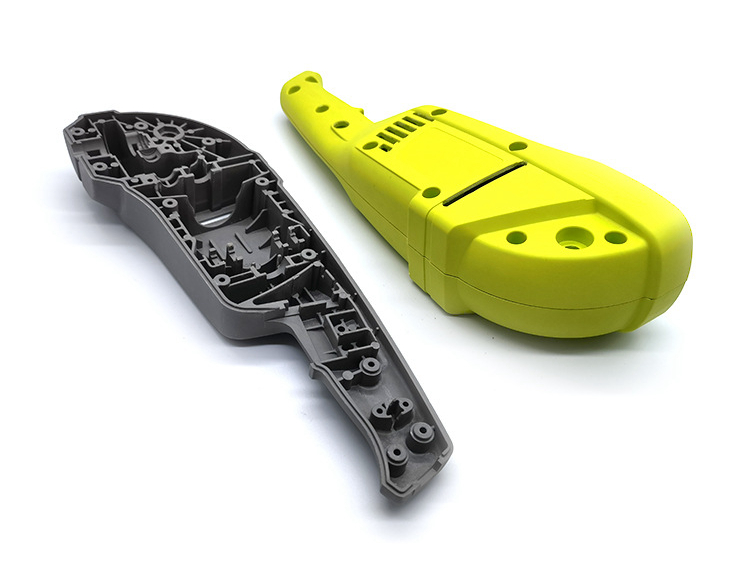

Overmolding enhances ergonomic design by combining soft and rigid materials in a single part, allowing engineers to shape products that naturally fit the human hand. By bonding thermoplastic elastomers, such as TPE-TPV or silicone rubber, onto substrates like nylon (PA) or ABS-PC, manufacturers achieve components that combine structural integrity with enhanced grip and tactile comfort.

Industry Applications of Ergonomic Overmolding

In power tools, overmolding minimizes vibration and reduces hand strain during extended use. This soft-touch layer improves handling precision, allowing operators to maintain better control and endurance.

For medical devices, ergonomic overmolding ensures that handheld instruments offer superior comfort and slip resistance—critical in delicate or prolonged procedures.

In consumer electronics, the method enables compact designs that feel smoother and safer to hold, such as protective cases or wearable enclosures.

Engineering Precision Through Multi-Material Design

By integrating overmolding with injection molding and insert molding, engineers can fine-tune thickness, surface texture, and pressure points. This ensures each product’s ergonomic performance aligns with human factors engineering principles, combining aesthetics, durability, and comfort seamlessly.