How does CNC machining ensure part consistency and repeatability?

How Does CNC Machining Ensure Part Consistency and Repeatability?

The Fundamentals of CNC Precision Control

CNC machining achieves exceptional consistency and repeatability by combining advanced software control with rigid mechanical systems. Key to this performance is the ability of CNC machines to execute identical toolpaths under tightly monitored parameters—ensuring that each part meets the same dimensional and surface quality standards, regardless of batch size or complexity.

Key Elements That Ensure Consistency and Repeatability

Digital G-Code Programming CNC systems rely on G-code, a numerical language that precisely defines tool movements. Once optimized, these instructions guarantee identical operations across thousands of parts, with deviations held within ±0.01 mm.

High-Rigidity Machine Design Industrial-grade CNC machines feature ball screw drives, linear guides, and rigid cast-iron frames that minimize vibration and deflection—critical for maintaining tolerance stacks in high-precision parts.

Closed-Loop Feedback Systems Servo motors paired with encoders continuously adjust for real-time axis correction. For example, position feedback ensures that if the tool deviates by even 0.001 mm, automatic compensation corrects the path instantly.

Tool Wear Compensation In automated runs, tool presetters and in-cycle measurement systems detect wear or offset shifts. This allows real-time updates to tool length and diameter offsets, maintaining consistent cut dimensions over extended runs.

Thermal Compensation Advanced CNC systems integrate thermal sensors and compensation algorithms to address heat-induced expansion. This is essential for maintaining micron-level repeatability in long production cycles.

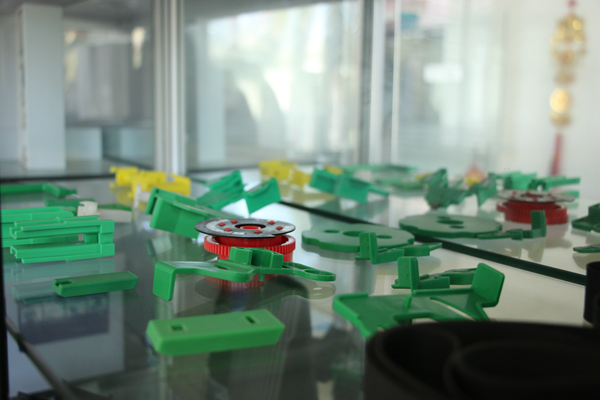

Fixturing and Setup Repeatability Custom fixtures and precision jigs designed using CNC prototyping services ensure exact part positioning. Repeatable clamping minimizes Z-axis and XY misalignments between cycles.

Automated Quality Control Integration Many systems incorporate in-process measurement using touch probes or laser scanners. Deviations beyond specified tolerances trigger real-time alerts or part rejection.

Real-World Industry Metrics

According to a 2024 NIST study on manufacturing repeatability, modern 3-axis and 5-axis CNC systems maintained dimensional deviations within ±0.005 mm over 10,000-part production runs under controlled environments. In aerospace machining, achieving Cpk > 1.67 (process capability index) is standard, proving Six Sigma-level consistency.

Manufacturing Services That Support Consistency

Neway enhances part consistency through:

5-Axis CNC Machining for complex parts requiring precision from multiple orientations

Superalloy CNC Machining with high thermal and dimensional stability

CNC Prototyping to validate fixturing, toolpaths, and setup repeatability before mass production

With ±0.01 mm accuracy, ISO-standard QA protocols, and automated inspection, we ensure stable, repeatable production for every part—regardless of complexity or batch size.