Are there any specific design considerations to consider when planning for overmolding production?

Integrating Functionality and Manufacturability

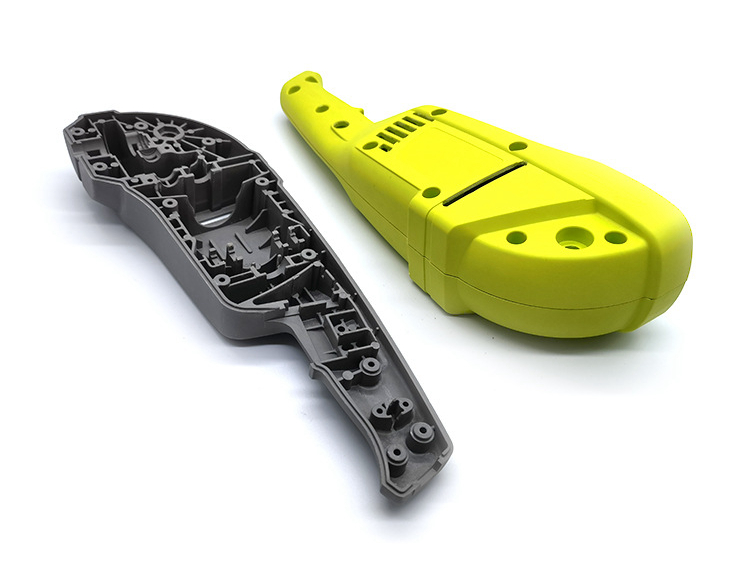

When planning for overmolding production, engineers must strike a balance between design aesthetics, structural integrity, and manufacturability. The process involves molding one material—usually a soft elastomer—over a rigid substrate, requiring precise control of material compatibility, bonding interfaces, and mold geometry. Well-planned designs can prevent delamination, warpage, or poor adhesion, ensuring both performance and appearance meet specification.

1. Material Compatibility and Adhesion

Selecting compatible materials is the foundation of a successful overmolding process. Substrates such as polycarbonate (PC), ABS, and nylon (PA) bond well with soft materials like thermoplastic elastomers (TPE) or TPU. For applications requiring extreme durability or chemical resistance, such as those in the automotive or medical device industries, compatibility testing is crucial to ensure long-term adhesion. Mechanical interlocks or undercuts can also be designed into the substrate to reinforce bonding strength.

2. Mold Design and Flow Optimization

A well-designed mold ensures accurate material flow and alignment between the substrate and overmold. Gate placement should promote even distribution of molten material, while venting helps avoid air traps. For multi-material parts, the precision of plastic injection molding directly affects dimensional accuracy. Using simulation tools during the rapid molding prototyping phase allows engineers to refine mold design and validate filling behavior before committing to mass production.

3. Wall Thickness and Shrinkage Management

Uniform wall thickness helps maintain consistent cooling and minimizes shrinkage differentials between the two materials. Overly thick elastomer layers can cause warpage or soft spots. Strategic ribbing or thin-section transitions can balance structural rigidity with weight efficiency, especially for power tool or consumer electronics housings where tight tolerances are required.

4. Surface Finish and Aesthetic Control

Surface finish plays a key role in tactile quality and appearance. Processes like polishing or in-mold decoration (IMD) can be integrated to achieve uniform gloss or matte textures. Textured surfaces also improve adhesion and mask potential flow marks from the molding process.

5. Dimensional Tolerances and Tooling Alignment

Since overmolding involves multiple molding stages, precise alignment between molds is essential. Tolerance stacking can affect bonding accuracy and final part dimensions. Collaborating with a custom parts manufacturing service experienced in multi-shot molding ensures consistency, optimized cycle times, and minimal rework.