Can 3D printed parts achieve the same strength as traditionally manufactured parts?

Can 3D-Printed Parts Achieve the Same Strength as Traditionally Manufactured Parts?

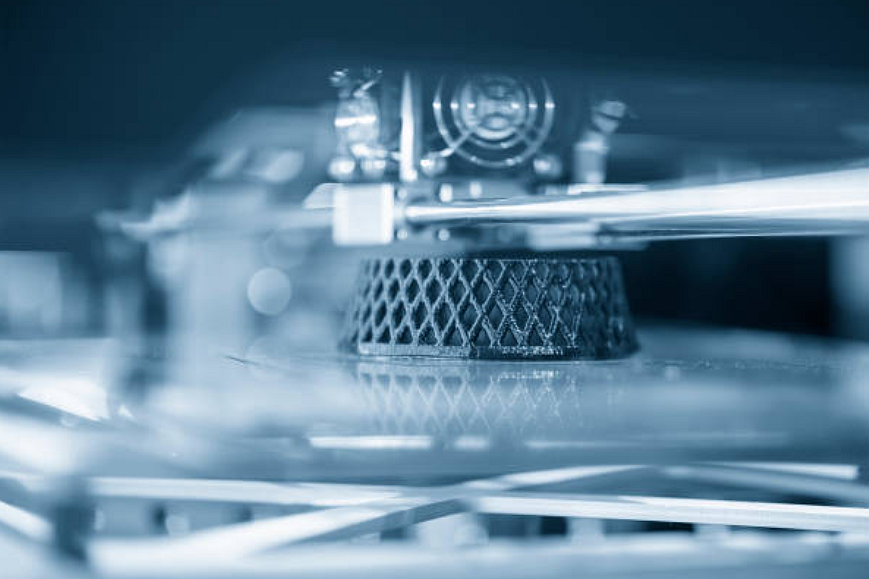

Evaluating Strength and Performance in Additive Manufacturing

The mechanical strength of 3D printed parts depends on multiple factors—material, printing process, orientation, and post-processing. While 3D printed parts can match or even exceed the strength of traditionally manufactured components in some applications, there are specific limitations based on anisotropy and surface integrity.

When 3D Printing Matches Traditional Strength

With metal 3D printing technologies such as DMLS (Direct Metal Laser Sintering) and SLM (Selective Laser Melting), mechanical properties can be equivalent to forged or cast metals:

Inconel 718 printed via DMLS exhibits tensile strength up to 1,250 MPa, similar to wrought forms.

Ti-6Al-4V printed via SLM delivers a yield strength of ~880 MPa, commonly used in aerospace and medical implants.

AlSi10Mg parts show up to 320 MPa tensile strength post-heat treatment, comparable to die-cast aluminum.

Polymer 3D Printing Strength Comparisons

High-performance polymers like PEEK or Ultem (PEI) printed via FDM can achieve tensile strengths >90 MPa, matching injection-molded parts in certain cases.

Reinforced filaments such as carbon-fiber-filled nylon can exceed 140 MPa, suitable for functional prototypes, jigs, and fixtures.

Strength Limitations to Consider

Anisotropy Parts printed layer-by-layer tend to have lower Z-axis strength. Interlayer adhesion is typically 30–50% weaker than intralayer strength unless optimized.

Surface Porosity and Defects Minor voids or unmelted powder in metal prints can reduce fatigue resistance compared to machined or forged parts.

Lack of Post-Processing. Many 3D printed parts need heat treatment, HIP (Hot Isostatic Pressing), or CNC finishing to achieve optimal mechanical properties and surface finish.

Hybrid Solutions for Enhanced Strength

To meet or exceed traditional strength benchmarks, Neway offers:

Metal 3D Printing + Post Heat Treatment for aerospace-grade performance

3D Printing with CNC Finishing to improve dimensional accuracy and fatigue life

Material Selection Support to align the print process and material with the strength requirements

With ±0.01 mm accuracy and access to aerospace, medical, and industrial-grade materials, Neway ensures your 3D printed parts perform reliably under real-world loads.