What industries benefit the most from adopting over-molding processes?

Cross-Industry Advantages of Overmolding

Overmolding is one of the most versatile manufacturing processes, combining design freedom, functional performance, and cost efficiency. By integrating multiple materials—typically a rigid plastic substrate and a soft elastomeric layer—manufacturers can enhance grip, impact resistance, and sealing performance while improving product aesthetics. This makes overmolding a preferred choice across a wide range of industries where ergonomics, durability, and visual appeal are essential.

Automotive Industry

In the automotive industry, overmolding is widely used for interior and exterior components, including knobs, handles, gaskets, and seals. Combining nylon (PA) or polycarbonate (PC) substrates with thermoplastic elastomers (TPE) or TPU provides improved vibration damping and wear resistance. The result is quieter operation, enhanced user comfort, and better long-term durability—key performance criteria for modern vehicles.

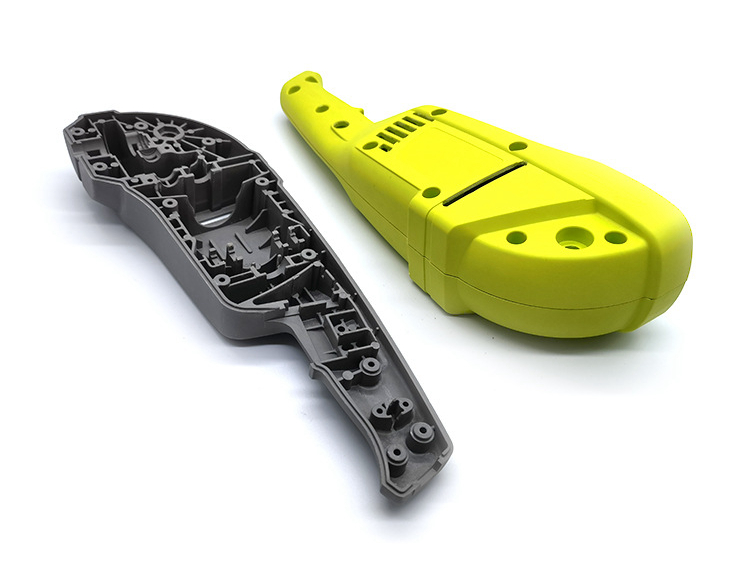

Consumer Electronics and E-Mobility

For consumer electronics and e-mobility, overmolding offers a seamless combination of function and form. Devices such as handheld controllers, chargers, and battery housings utilize overmolded grips and seals to achieve sleek designs that provide reliable protection against impact and moisture. By pairing ABS or PBT substrates with elastomers, manufacturers can achieve compact, ergonomic designs that require no additional fasteners or gaskets.

Medical and Healthcare Devices

In the medical device sector, overmolding improves both hygiene and patient comfort. Soft-touch handles, catheter grips, and diagnostic housings often combine rigid engineering plastics with biocompatible silicone rubber or TPU layers. These materials ensure secure handling, chemical resistance, and compatibility with sterilization processes.

Power Tools and Industrial Equipment

Power tools benefit greatly from overmolding’s shock-absorbing and vibration-damping capabilities. A combination of plastic injection molding and overmolding produces robust housings and grips that maintain integrity under repetitive use. Elastomeric overmolds also enhance operator comfort and protect internal electronics from dust and impact damage.

Telecommunications and Lighting Solutions

In telecommunication and lighting applications, overmolding creates weatherproof seals, grommets, and connectors. The process ensures long-term environmental protection while maintaining sleek aesthetics for both indoor and outdoor installations.