What factors should be considered when selecting materials for Over Molding?

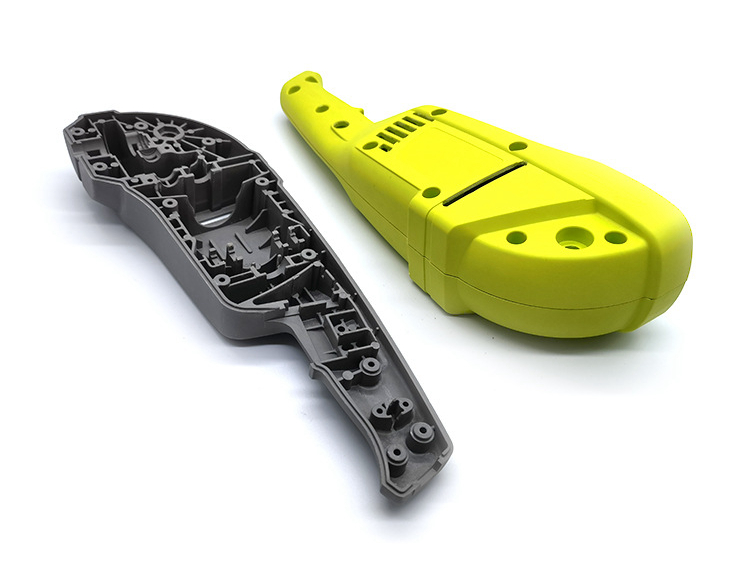

Selecting the right materials for overmolding is critical to achieving a high-quality, durable, and functional multi-material component. The process involves molding a soft, flexible material (the overmold) over a rigid substrate. The success hinges on the compatibility and interaction between these two materials.

1. Substrate and Overmold Material Compatibility

The foremost consideration is how the two materials will adhere to each other.

Chemical Bonding: This is the strongest bond, formed when the materials are chemically compatible. For instance, bonding a TPE or TPU over PP can create a molecular-level fusion. Our Overmolding Service expertise is crucial in recommending proven material pairs.

Mechanical Interlocking: When a chemical bond isn't possible, the substrate can be designed with undercuts, holes, or a textured surface to allow the overmold to flow in and create a physical lock.

Adhesion Promoters: In some cases, a special coating or primer may be applied to the substrate to enhance adhesion.

2. Material Properties and Performance Requirements

The functional needs of the final part dictate the material choices.

Substrate Rigidity: The base part must be rigid enough to withstand the overmolding process. Common substrates include ABS, PC, Nylon (PA), and metals. Explore our Plastic Injection Molding Service for substrate options.

Overmold Flexibility and Feel: The overmold material, often sourced from our Insert Molding Service portfolio, is selected for its properties such as soft-touch grip, shock absorption, or vibration damping. TPE, TPU, and Silicone rubber are popular choices.

Environmental Resistance: Consider the operating environment. Will the part be exposed to chemicals, UV light, extreme temperatures, or moisture? Materials like TPU offer excellent abrasion resistance, while some grades can withstand oils and fuels.

3. Manufacturing and Design Considerations

The practicalities of the manufacturing process cannot be overlooked.

Shrinkage Rates: Different materials shrink at different rates as they cool. Mismatched shrinkage can lead to warping or delamination. Our engineers simulate this to ensure dimensional stability.

Melt Temperature: The overmold material must have a melting temperature lower than the substrate's heat deflection temperature. Otherwise, the substrate could deform during the second shot.

Surface Preparation: The substrate must be clean and free of contaminants. Techniques such as plasma cutting for metal substrates or specific surface treatments can prepare the surface for optimal bonding.

4. Regulatory and Aesthetic Needs

Finally, the application sector and visual design play a key role.

Industry Certifications: For Medical Device or Consumer Electronics applications, materials may need to be biocompatible (e.g., USP Class VI) or have specific flammability ratings (e.g., UL94).

Aesthetics: Overmolding enables the creation of color combinations and soft-touch surfaces that enhance brand identity and the overall user experience. Finishing techniques like Polishing the mold can achieve high-gloss or matte finishes on the overmold.