How quickly can parts be produced using rapid molding techniques?

How Quickly Can Parts Be Produced Using Rapid Molding Techniques?

Accelerated Production Timelines with Rapid Molding

Rapid molding techniques are engineered for speed, minimizing lead times while delivering functional, production-grade parts. Unlike traditional injection molding that requires weeks or even months for steel tooling fabrication, rapid molding uses aluminum or hybrid soft molds, enabling parts to be delivered in as little as 7 to 14 days from final design approval.

Typical Lead Times by Process Phase

Phase | Time Required |

|---|---|

DFM Review and Mold Design | 1–3 days |

Mold Fabrication (Aluminum Tool) | 3–7 days |

First Article Production | 1–2 days |

Final Part Delivery | 7–14 days (standard) |

Expedited Options | As fast as 5 business days |

This accelerated timeline includes both tooling and initial part production—ideal for engineering validation, pre-series builds, and time-sensitive production demands.

Factors Influencing Production Speed

Part Complexity Simpler parts with uniform wall thickness and minimal undercuts mold faster. Complex geometries may extend tool design by 1–2 days.

Material Selection Readily available thermoplastics like ABS, PC, and PP can be sourced immediately. Engineering materials like PEEK or Ultem (PEI) may require lead time for procurement and tooling temperature adjustments.

Mold Type and Cavity Count: Single-cavity aluminum tools are faster to fabricate. Multi-cavity or complex lifter/ejector designs may increase mold lead time by 2–3 days.

Post-Molding Operations Secondary processes like CNC trimming, painting, or inspection (if needed) may add 1–3 days, depending on part volume and requirements.

When Rapid Molding Is Ideal

Bridge Production: Covers production gaps before mass manufacturing ramps up

Design Validation: Functional testing of final material parts before tool commitment

Pilot Launches: Small-batch production runs for early customer feedback

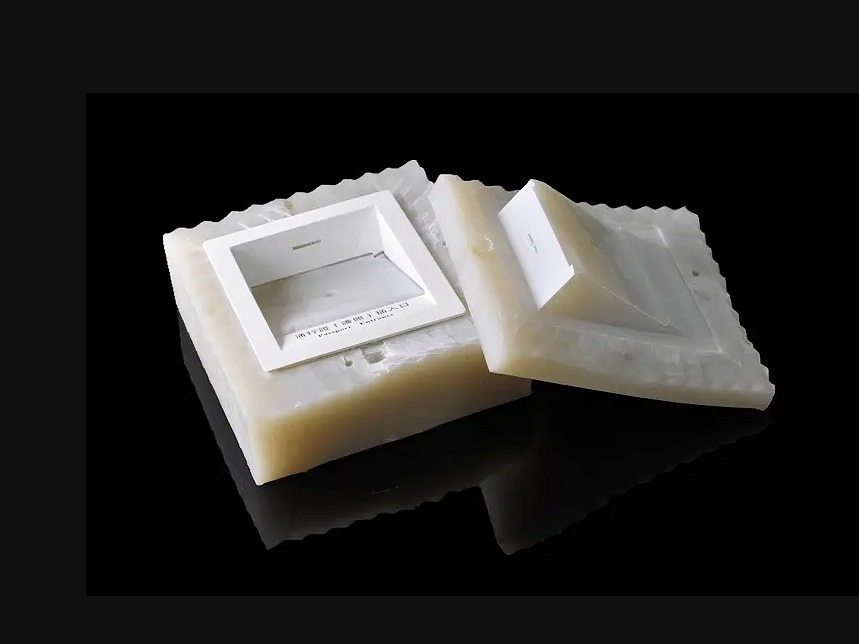

Neway’s Rapid Molding Capabilities

Neway delivers rapid-molded parts with:

Fast Mold Builds in as little as 5 business days

Material Consultation to align resin selection with application timelines

Post-Molding Services, including inspection, finishing, and low-volume packaging

With ±0.05 mm tolerance, scalable production, and global shipping, Neway ensures your time-to-market goals are met without compromising quality.