Which materials are best suited for the overmolding process?

Which Materials Are Best Suited for the Overmolding Process?

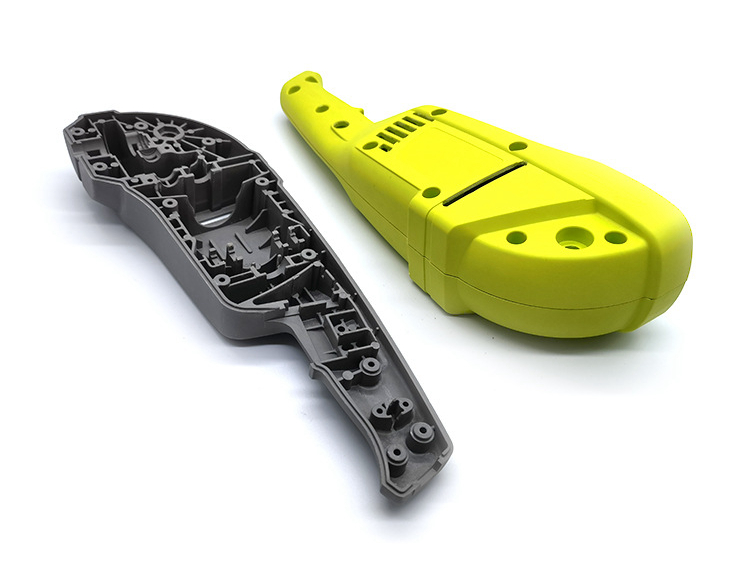

With the global shift toward product miniaturization, user-centric design, and sustainability, overmolding has become a critical solution in multi-functional part manufacturing. By combining rigid and soft materials in a single component, overmolding enhances product performance while reducing assembly costs and material waste. The success of this process depends heavily on selecting the right substrate and overmold material combination.

Substrate Materials (First Shot/Base Layer)

1. ABS (Acrylonitrile Butadiene Styrene)

Cost-effective and dimensionally stable

Compatible with: TPE, TPU, Santoprene

Common in consumer electronics and tool handles

Learn more: ABS Injection Molding

2. PC (Polycarbonate)

Impact-resistant, thermally stable (up to 135 °C)

Compatible with: TPU, TPE (bonding grade required)

Ideal for transparent housings and medical casings

Learn more: PC Injection Molding

3. Nylon (PA6, PA66)

High strength and fatigue resistance

Compatible with: Modified TPUs with adhesion promoters

Used in automotive engine components and wear-resistant parts

Learn more: Nylon Injection Molding

4. PBT (Polybutylene Terephthalate)

Excellent for electrical and automotive applications

Compatible with: Certain TPEs, TPVs

Supports precision molding for connectors and housings

Learn more: PBT Injection Molding

5. Polypropylene (PP)

Lightweight, chemically resistant

Compatible with: TPO, TPE-O, selected TPVs

Preferred for high-volume, cost-sensitive products

Learn more: PP Injection Molding

Overmold Materials (Second Shot/Outer Layer)

1. TPE (Thermoplastic Elastomer)

Shore A hardness range: 30–90

Offers high elasticity and grip

Bonds well to ABS, PP, PC (with bonding grade)

Learn more: TPE/TPU Injection Molding

2. TPU (Thermoplastic Polyurethane)

Abrasion resistance up to 3x higher than TPE

Excellent chemical durability

Used in rugged wearables, industrial housings

3. Silicone Rubber

Ideal for medical use due to biocompatibility

Requires LSR processing; bonding with plastics may need surface priming

Stable at −50 °C to 200 °C

Learn more: Silicone Rubber Molding

4. TPV (Thermoplastic Vulcanizate)

Flexible across −40 °C to 125 °C

Suitable for sealing and weather-resistant assemblies in automotive and outdoor devices

Material Compatibility Tips

Melt temperature difference between materials should be ≤ 30 °C

Surface preparation or primers are essential for low-energy plastics (e.g., PP)

Mechanical interlocks are recommended when bonding is weak

Adhesion testing (peel strength ≥ 5 N/cm) is required for critical interfaces

Why Material Selection Matters at Neway

Neway Precision integrates advanced simulation and testing during design to ensure optimal adhesion and performance. We offer:

Substrate-overmold pair evaluation for strength, elasticity, and chemical resistance

Real-world testing for sealing, fatigue, and thermal cycling

Full support through consultative engineering and prototype validation