Aluminum Die Casting | NVIDIA GPU Frame Manufacturer

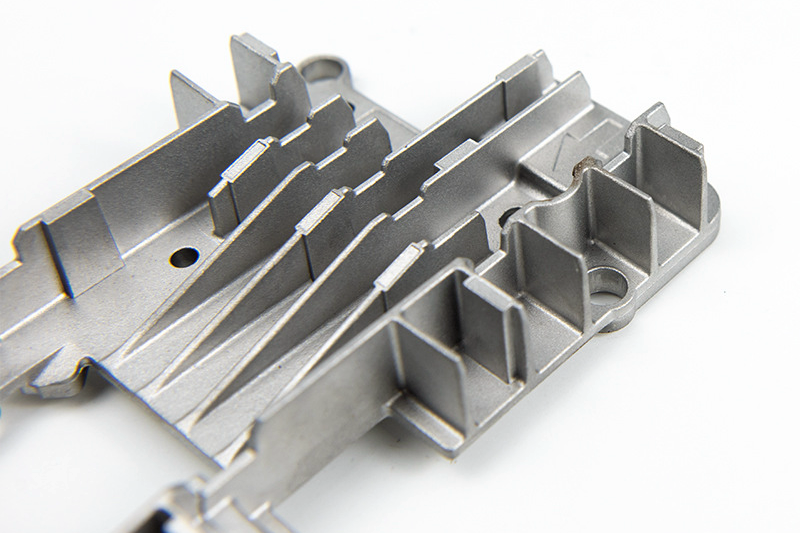

Custom Aluminum Die Casting for NVIDIA: Precision GPU Bracket Manufacturing Case Study

Project Background and Client Overview

NVIDIA, a leading global manufacturer of graphics processing units (GPUs), maintains stringent performance and precision requirements for structural components. Due to their high standards, NVIDIA selected Neway Precision as a strategic partner for manufacturing non-standard aluminum die-cast GPU brackets, specifically appreciating our capabilities in rapid delivery, custom parts manufacturing, and rigorous quality control measures.

Project Requirements and Technical Challenges

NVIDIA’s GPU bracket design required aluminum components that were lightweight, highly durable, heat-resistant, and dimensionally accurate. These GPU brackets demanded precise CNC finishing tolerances of ±0.02 mm and surface treatments such as anodizing to enhance aesthetics and thermal performance.

A major challenge was the development of complex molds, due to the unique geometric configurations of NVIDIA’s design. Our team successfully overcame these difficulties by employing advanced simulation tools to optimize mold flow and minimize porosity issues.

Manufacturing Process and Solutions

Process Step | Description |

|---|---|

Mold Design & Flow Analysis | Utilized CAE software for mold-filling simulation to minimize defects and gas porosity. |

Aluminum Die Casting | Chose high-quality ADC12 aluminum alloy to balance strength and machinability. |

CNC Precision Machining | Precision machined bracket surfaces and mounting holes, ensuring assembly accuracy within ±0.02 mm tolerances. |

Surface Finishing | Applied anodizing treatment for superior aesthetics, corrosion resistance, and enhanced heat dissipation capabilities. |

Critical control points during production included maintaining wall thickness tolerances at ±0.1 mm and flatness tolerances below 0.05 mm, ensuring each bracket met NVIDIA's stringent specifications.

Project Outcome and Client Feedback

The final products were delivered within agreed timelines, accompanied by comprehensive quality inspection and dimensional verification reports, affirming compliance with NVIDIA’s rigorous quality standards.

Feedback from NVIDIA’s engineering team highlighted the impressive structural stability and excellent thermal conductivity of the brackets. They specifically praised Neway Precision’s meticulous control over dimensional accuracy and surface quality, affirming our ability to meet their high-performance expectations.

Conclusion and Strategic Impact

This partnership demonstrates Neway Precision’s advanced technical expertise and boosts our international reputation in manufacturing precision aluminum alloy structural components. It underscores our capability to deliver tailored solutions for high-end clients, reinforcing our position as a trusted provider in custom, non-standard aluminum die casting.

Call-to-Action

Explore Neway’s professional manufacturing services tailored to meet your specific needs:

FAQs

What specific aluminum alloys are suitable for high-performance GPU brackets?

How does Neway Precision ensure dimensional accuracy in CNC machining processes?

What surface treatment options best improve thermal conductivity in GPU components?

What are common challenges in complex mold development for die casting?

How quickly can Neway Precision deliver custom aluminum die-cast components from prototyping to mass production?