How quickly can rapid injection molded parts be produced?

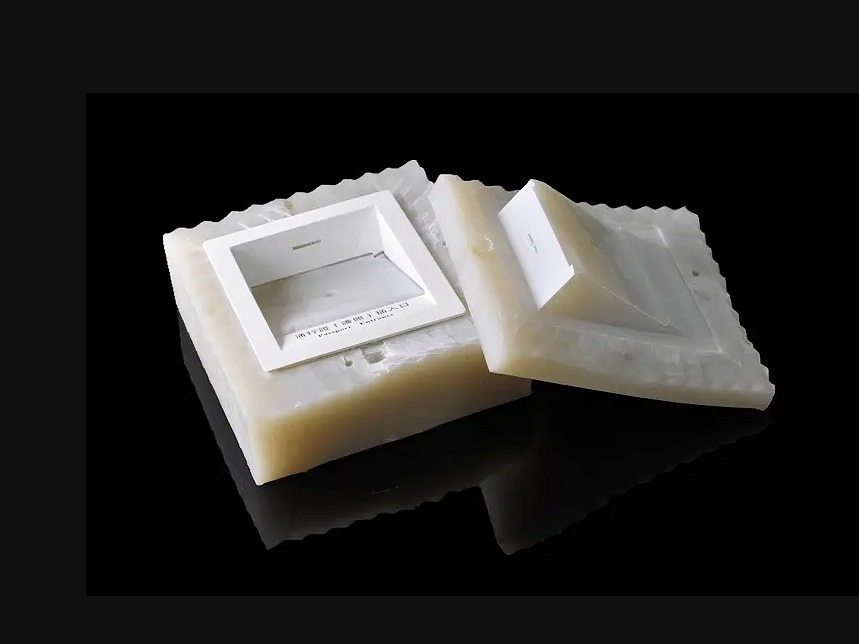

Rapid injection molded parts can typically be produced within 1 to 4 weeks, depending on design complexity, material choice, and production volume. This expedited turnaround is achievable due to advanced CNC machining techniques for molds and highly optimized production workflows. Neway Precision specializes in rapid injection molding, offering parts delivery in as fast as 7 days for straightforward geometries or urgent prototyping requirements.

Key factors influencing delivery times include:

Mold Complexity: Simple molds (without complex slides or cores): typically 5–10 days. Complex molds (with slides, undercuts, or cores): usually 10–20 days

Material Availability: Standard materials (ABS, PC, Nylon): immediately available, minimal delay.s Specialty materials (PEEK, LCP): additional procurement time may be required

Production Volume: Small batches (50–500 units): typically within 1–2 weeks Larger production runs (500+ units): generally around 3–4 weeks or more

To fully benefit from rapid injection molding and ensure optimal turnaround, consider leveraging Neway Precision’s comprehensive suite of services, including Plastic Injection Molding, CNC Machining Prototyping, and 3D Printing Prototyping. With over 20 years of industry experience, precision of ±0.01mm, and swift global delivery capabilities, Neway Precision efficiently meets diverse, urgent prototyping and production requirements across automotive, aerospace, medical, and consumer electronics sectors.