Gigabyte | Aluminum Die Casting Electronic Accessories

Project Background and Client Overview

Gigabyte, a world-renowned manufacturer of high-performance computing hardware, required premium aluminum electronic accessories for its advanced graphics processing units (GPUs). To meet the stringent demands of thermal performance, mechanical strength, and visual appeal, Gigabyte partnered with Neway Precision. Leveraging our expertise in aluminum die casting, CNC machining, and professional painting processes, we successfully delivered a customized GPU frame solution tailored to Gigabyte’s technical and aesthetic standards.

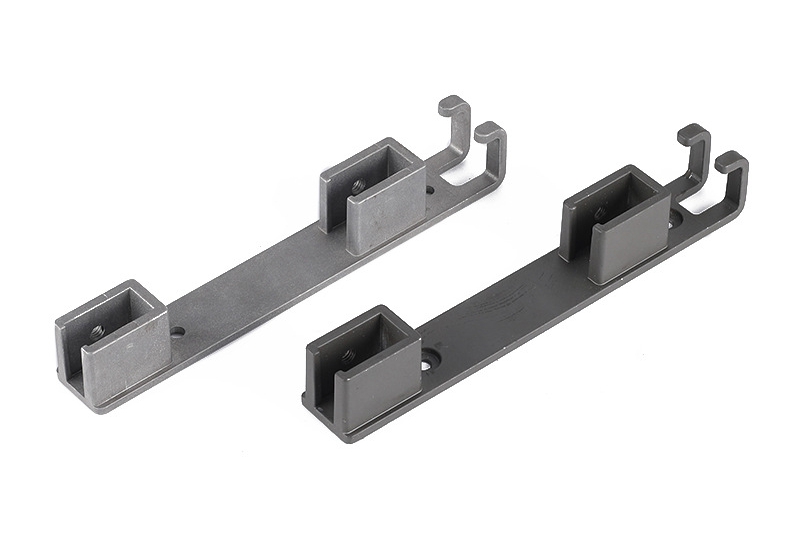

Product Introduction

The aluminum GPU frame serves as both a structural and thermal component within Gigabyte’s high-end graphics card assembly. It is engineered to support the card’s PCB and heatsink while contributing to heat dissipation and system rigidity. The frame's durability, dimensional precision, and cosmetic quality directly influence the performance and perceived quality of Gigabyte’s GPU lineup.

Client Introduction

Gigabyte Technology is a global leader in PC hardware and gaming systems, known for innovation in motherboard, graphics card, and peripheral design. Gigabyte’s premium AORUS series emphasizes high performance, aggressive styling, and advanced thermal solutions—necessitating flawless mechanical components like the GPU frame.

Project Requirements and Technical Challenges

Gigabyte’s project posed several technical challenges and requirements:

Lightweight yet high-strength aluminum alloy for thermal and mechanical reliability.

Tight dimensional tolerances (±0.02 mm) for proper alignment with the GPU PCB and heatsink.

Flawless painting with uniform texture and color matching the brand’s aesthetic.

Exceptional surface finish free of casting defects to meet both functional and visual quality standards.

Challenges included avoiding porosity during die casting, ensuring precise machining of mounting points and thermal contact surfaces, and achieving consistent surface quality across batches for large-volume production.

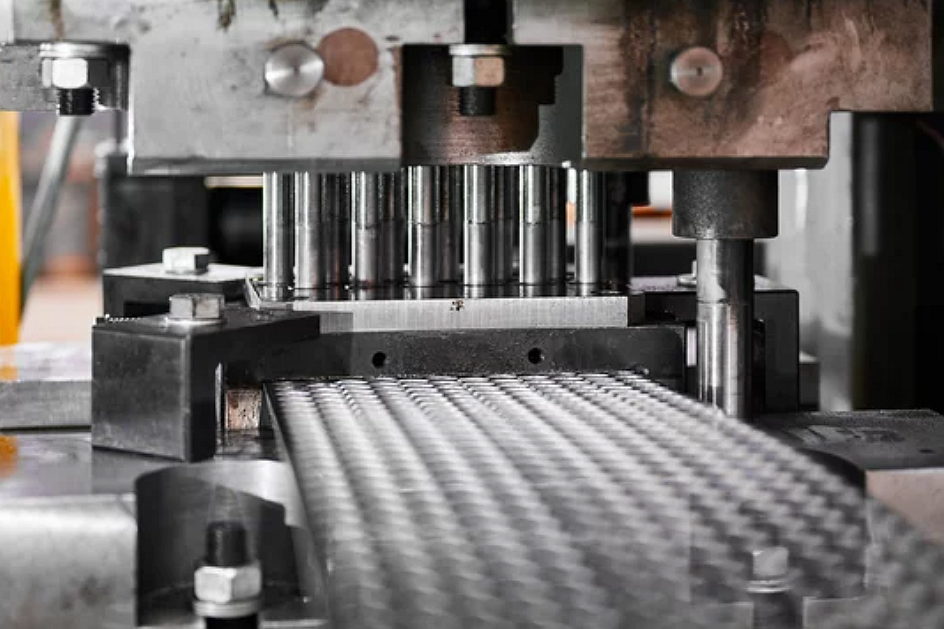

Manufacturing Process and Solutions

Process Step | Description |

|---|---|

Aluminum Die Casting | Employed A380 aluminum alloy to ensure thermal conductivity, structural strength, and castability. Advanced mold designs were used to prevent shrinkage and porosity. |

CNC Precision Machining | Performed high-accuracy CNC machining (±0.02 mm) on mounting holes, support structures, and heat-contact surfaces to ensure perfect fit and reliable GPU performance. |

Surface Painting | Applied industrial-grade painting with durable coatings, achieving excellent adhesion, abrasion resistance, and a matte-black finish in line with AORUS design standards. |

Throughout the process, Neway Precision employed real-time quality monitoring systems to ensure each frame conformed to Gigabyte's exacting quality benchmarks.

Project Outcome and Client Feedback

The final aluminum GPU frames were delivered within the project timeline, accompanied by comprehensive inspection reports including 3D scanning, CMM data, and surface finish certifications.

Gigabyte’s engineering team provided strong positive feedback, particularly noting the precision of machined surfaces and the consistency of the frame’s painted finish. The GPU frames were seamlessly integrated into Gigabyte’s graphics card assembly line, improving thermal stability and structural rigidity while maintaining the brand’s aggressive visual identity.

Photographs of the installed frame confirmed excellent alignment, cosmetic finish, and functional performance.

Conclusion and Strategic Impact

This collaboration with Gigabyte highlights Neway Precision’s capability in delivering high-performance structural components for advanced electronics. By integrating aluminum die casting, CNC machining, and surface painting, we successfully met the technical, aesthetic, and volume production demands of one of the world’s leading tech brands.

Call-to-Action

Explore Neway’s integrated manufacturing services for electronics and GPU structural components:

FAQs about Gigabyte Aluminum GPU Frame Project

What are the advantages of using A380 aluminum for GPU structural components?

How does CNC machining ensure proper thermal contact in GPU frames?

What surface preparation is necessary before painting die-cast aluminum parts?

How does Neway control quality during high-volume electronics component production?

What is the typical lead time for mass production of aluminum GPU frames?